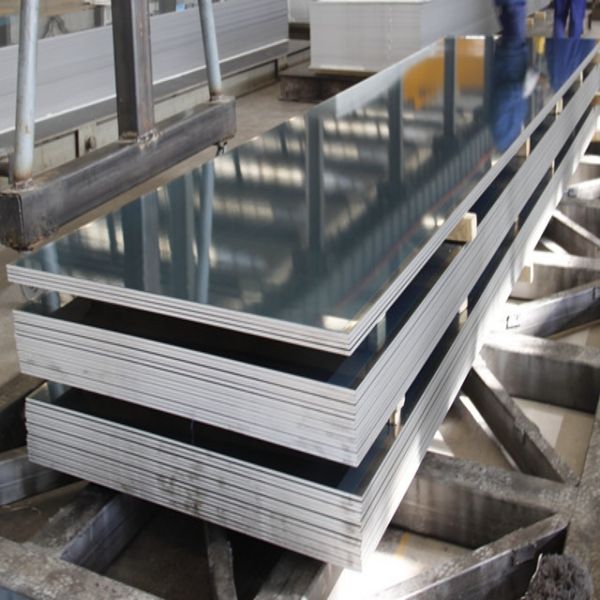

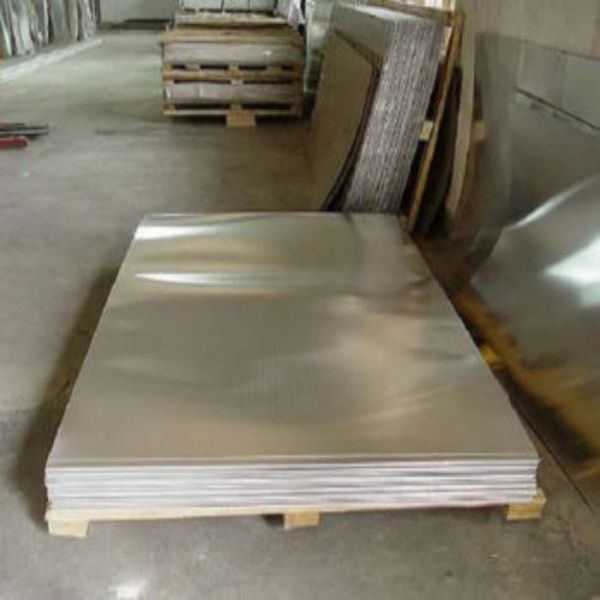

7000 Series Aluminum Alloy Sheet

7000 Series Aluminum Alloy Sheet:7050 aluminum plate is a high-strength heat-treatable alloy. It is based on 7075 aluminum alloy, which increases the Zn, Cu content and Cu / Mg ratio to increase the strength, and replaces Cr with Zr to overcome the quenching sensitivity problem and inhibit recrystallization. 7000 Series Aluminum Alloy Sheet is an alloy that has been around for decades and is known for its ability to remain strong over time. Although other alloys are available which are stronger on a one-off comparison basis, they do not necessarily demonstrate the longevity which the 7050 products can offer.

Aluminum plate 7050-T7451 is similar to the other popular 7000 series aluminum alloy 7075, however it is less quench sensitive.This allows the alloy to maintian strength properties over time better than other high strength alloys, especially in thick sections. 7050 aluminum also displays better corrosion resistance, exfoliation resistance, and toughness than standard high strength alloys making it very popular in the aerospace industry.

| Chemicai Composition(WT%) | |||||||||

| Grade | (Si) | (Cu) | (Mg) | (Zn) | (Mn) | (Ti) | (Cr) | Fe | (Al) |

| 7075 T651 | ≤0.4 | 1.2-2.0 | 2.1-2.9 | 5.1-6.1 | ≤0.3 | ≤0.2 | 0.18-0.28 | ≤0.5 | Balance |

| Mechanical Properties | |||||||||

| Yield Strength | Tensile Strength | El(%) | |||||||

| 503 Mpa | 572 Mpa | 11% | |||||||

| Difference between Aluminum Sheet 1060 H14 and 1060 H24 | |||||||||

| 7075 belongs to the high-strength heat-treatable alloy, aviation superhard aluminium alloy, high strength, good wear resistance, with extremely high strength and anti-exfoliation corrosion and stress corrosion fracture resistance. Good plasticity after solid solution treatment, good strengthening effect of heat treatment, good strength under 150℃ and especially good low-temperature strength. Widely used in mold processing, mechanical equipment, fixtures, aerospace industry, blow molding (bottle) mold, ultrasonic plastic welding mold, golf ball head, shoe mold, paper mold, foam molding mold, wax mold, mechanical equipment, used for making high-end aluminum alloy bicycle frame. It will be used for the first time as the body material of the smartphone OPPO N3 in 2014. | |||||||||

1.Can I have a sample order for Aluminum sheet products?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

2. What about the lead time?

Sample needs 3-5 days.

3. Do you have any MOQ limit for Aluminum sheet products order?

Low MOQ, 1pcs for sample checking is available.

4. How do you ship the goods and how long does it take to arrive?

We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional. For mass products, ship freight is prefered.

5.. Is it OK to print my logo on products?

Yes. OEM and ODM are available for us.

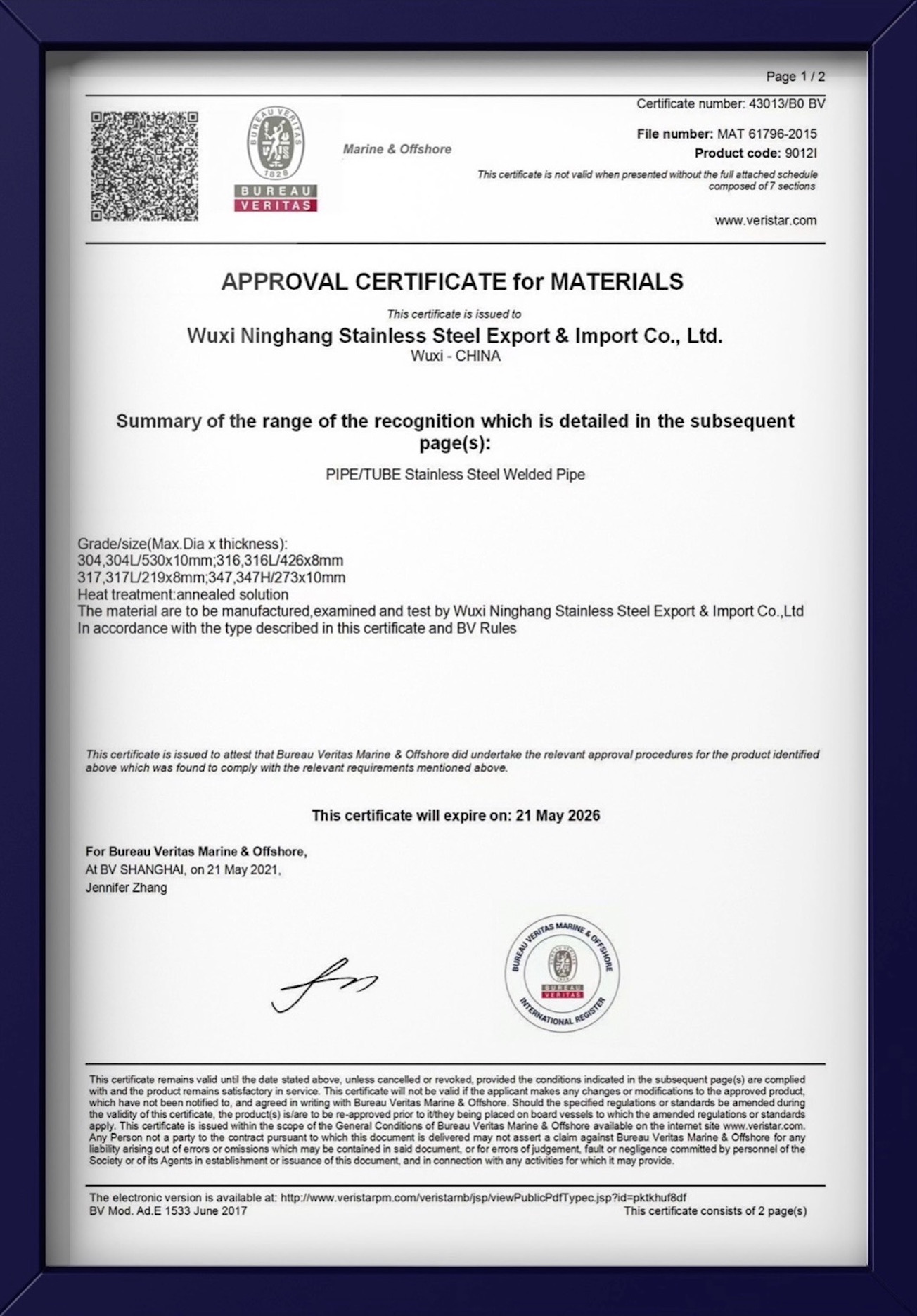

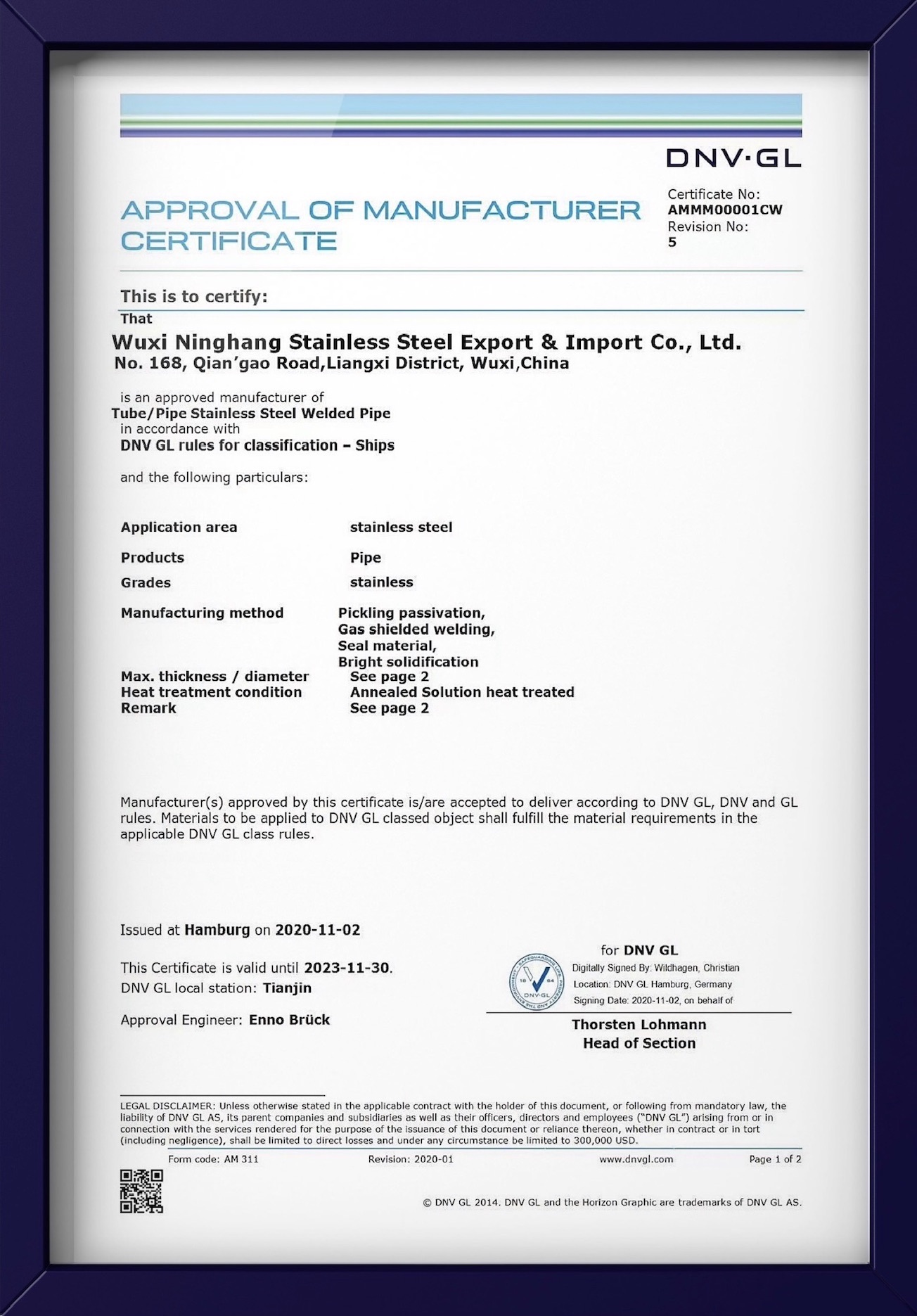

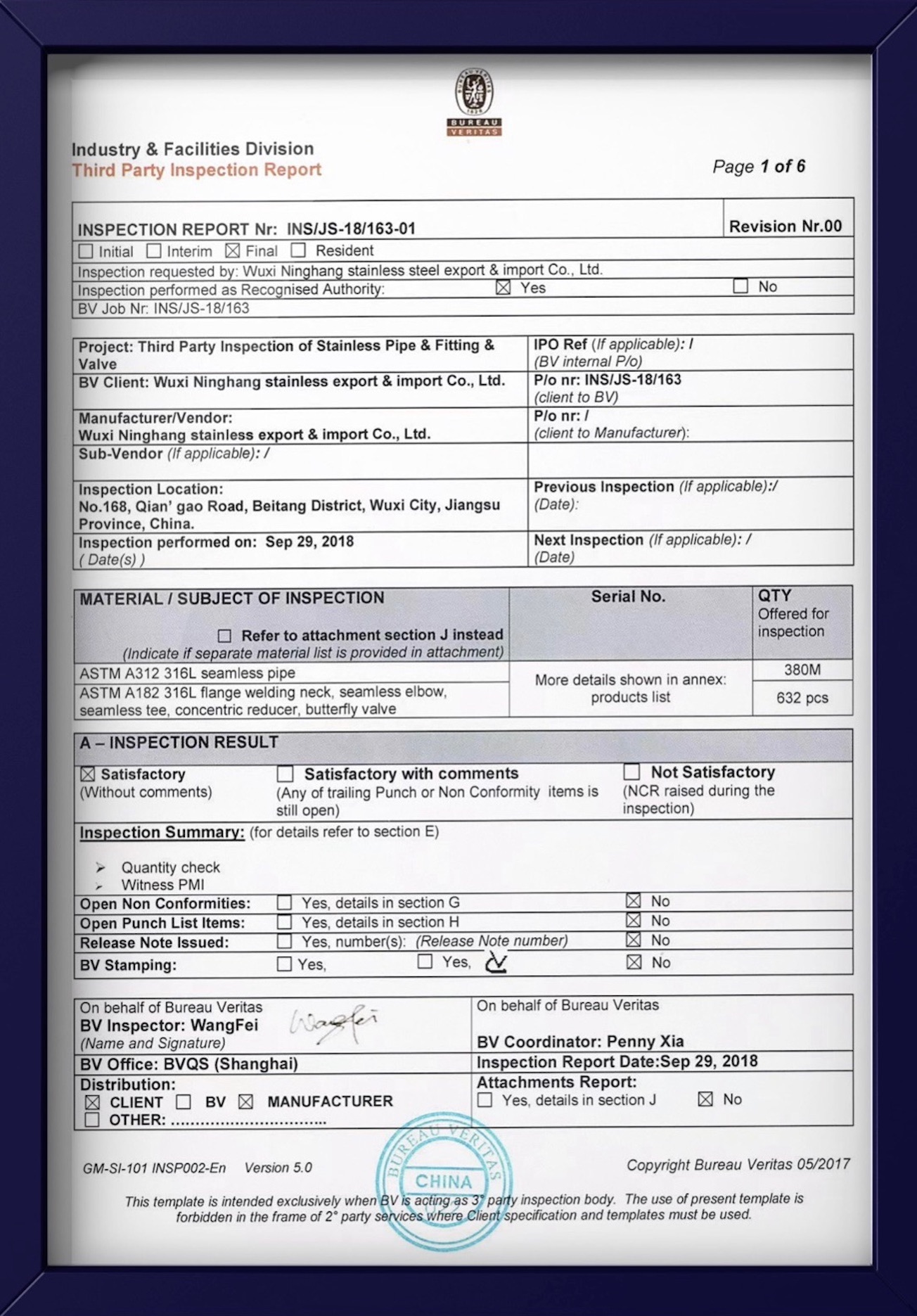

6.What's your warranty?

Mill test certificate;shipping inspection or any third party inspection in your site.