Aluminum alloy extrusion tube 6063

Aluminum alloy extrusion tube 6063:Aluminum alloy extrusion tube 6063are mainly divided into the following types.

Divided by shape: square tube, round tube, pattern tube, special-shaped tube, global aluminum tube.

According to the extrusion method: seamless aluminum tube and ordinary extrusion tube.

According to the precision: ordinary aluminum tubes and precision aluminum tubes, of which precision aluminum tubes generally need to be reprocessed after extrusion, such as cold drawing, fine drawing, and rolling.

According to thickness: ordinary aluminum tube and thin-walled aluminum tube.

| Specifications | |

| Grade | 6063 |

| Temper | T5/T6 |

| Length | 1-6m or as you request |

| Wall Thickness | 0.8-40mm |

| Shape | round,square,flat or as you request |

| Tradeterm | FOB,CFR,CIF,Ex-factory price |

| Payment term | TT,L/C, West Union and other |

| Package | Wooden case or as you request |

| Export to | North and South America, Africa, Europe,Oceania,etc |

| Application | Military machinery, Aircraft structure,truckwheel,Auto-industry and various structure |

| Alloy | Application field | |

|

1xxx |

1050 | Insulation, food industry, decoration, lamp, traffic signs etc. |

| 1060 | Fan blade, Lamps and lanterns, Capacitor shell, Auto parts, Welding parts. | |

| 1070 | Capacitor, Rear panel of vehicle refrigerator, charging point, heat sink etc | |

| 1100 | Cooker, building material, printing, heat exchanger, bottle cap etc | |

|

2xxx |

2A12

2024 |

Aircraft structures, rivets, aviation, machinery, missile components, the card wheel hub, propeller components, aerospace parts,car parts and various other structural parts. |

|

3xxx |

3003 3004

3005 3105 |

Aluminum curtain wall panel, aluminum Ceiling, Electric cooker bottom, TV LCD backboard, storage tank, curtain wall, building construction panel heat sink, billboard. Industrial floor, air conditioning, refrigerators radiators, Make-up board, Prefabricated house etc. |

|

5xxx |

5052 | Marine and transportation material, railway carriage's inner and outer cabinet, oil and chemical industry storage device,equipment and medical device panel etc. |

| 5005 | Marine applications, bodies of boats, buses, trucks and trailer. Curtain wall panel. | |

| 5086 | Ship board, deck, bottom and edge panel etc. | |

| 5083 | Tanker, oil storage tank, drilling platform, ship board, deck, bottom, welded parts and edge panel, railway carriage 's board,automotive and aircraft panel, cooling device and automotive molding etc. | |

| 5182 | ||

| 5454 | ||

| 5754 | Tanker body, marine facilities, pressure container, transportation etc. | |

|

6xxx |

6061

6083 6082 |

Railway inside and outside parts, board and bed plate. Industry molding

Highly stressed applications includes Roofing construction,transportation, and marine as well as mould. |

|

6063 |

Auto parts, architectural fabrication, window and door frames, aluminum furniture, electronic components as well as various consumer durable products. | |

|

7xxx |

7005 | Truss, rod/bar and the container in transportation vehicles; Large-sized heat

exchangers. |

| 7050 | Molding (bottles) mode, ultrasonic plastic welding mold, golf head, shoe mold, paper and plastic molding, foam molding, lost wax mold, templates, fixtures, machinery and equipment. | |

| 7075 | Aerospace industry, military industry, electronic etc. | |

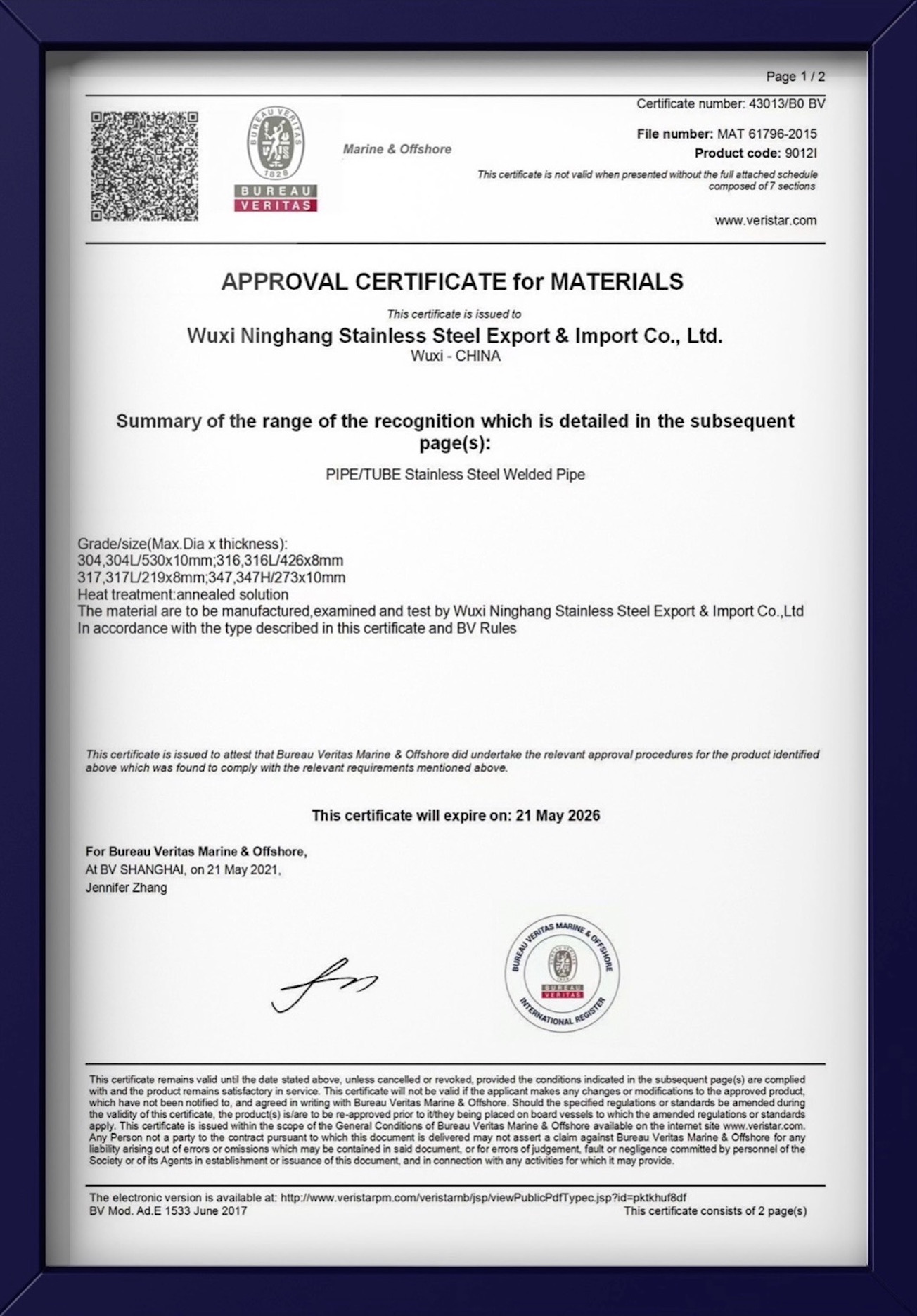

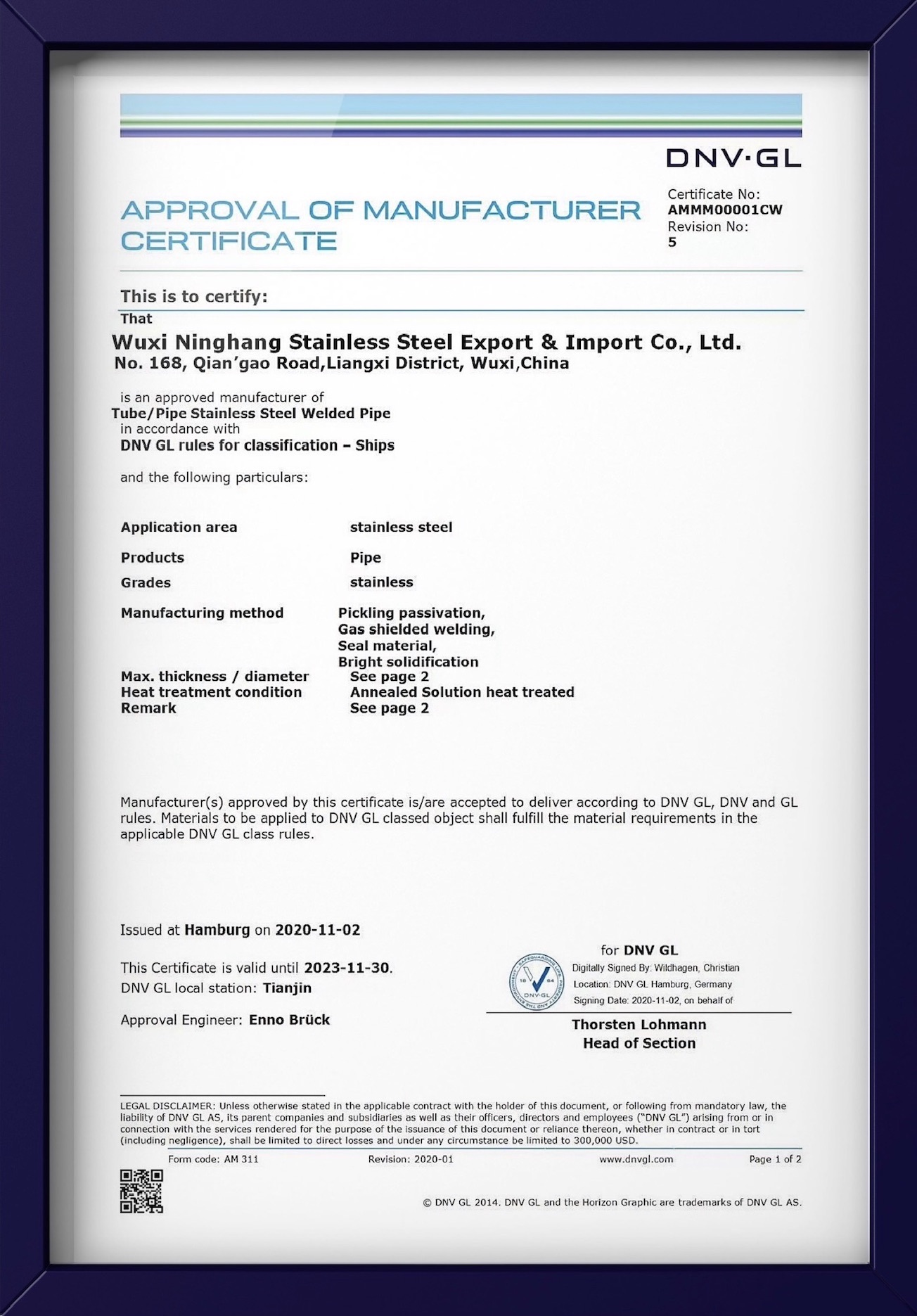

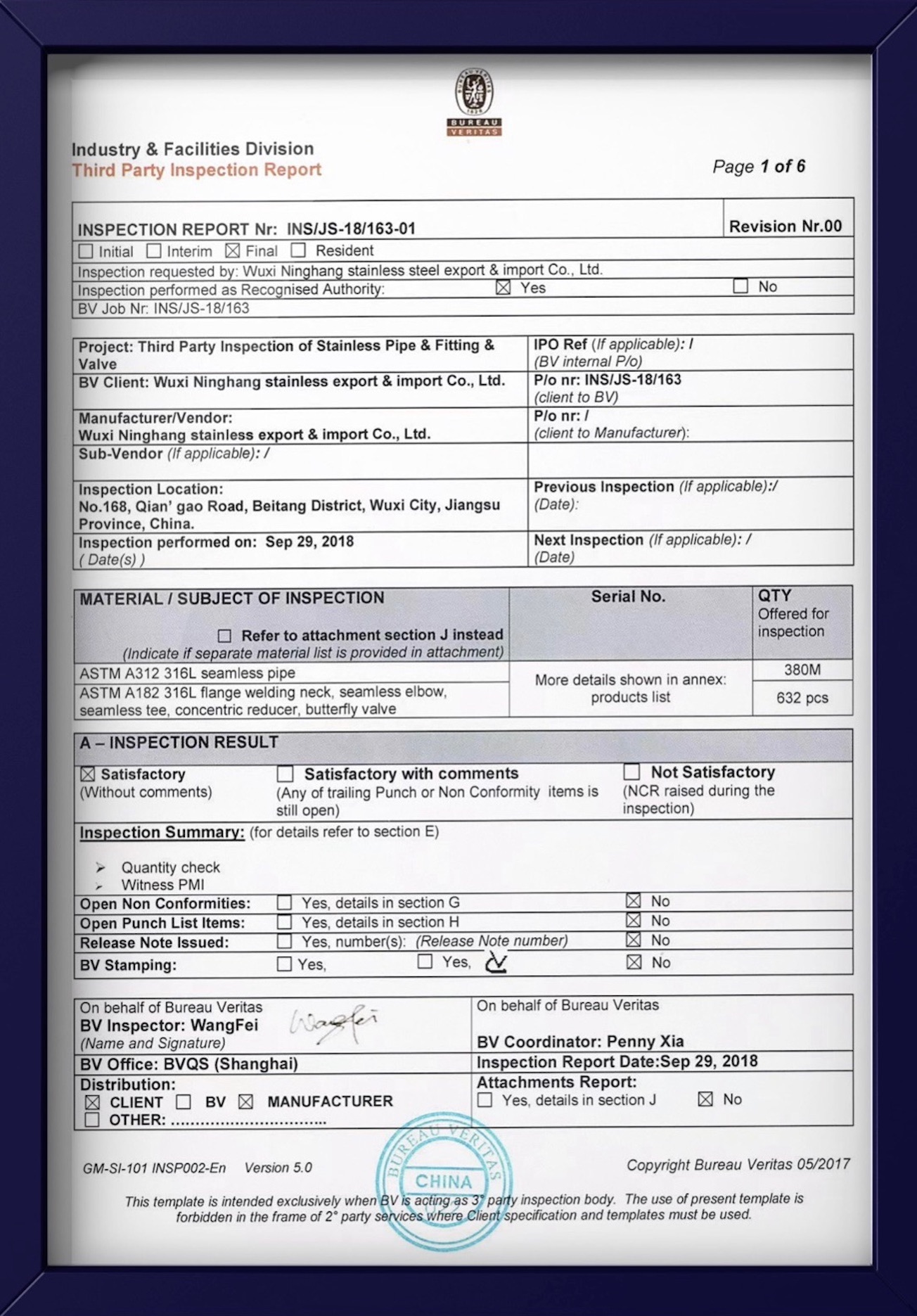

1.How to ensure the quality of your products?

IS09000, client requirements, product standards, strict inspection to control raw material, production process and final products.

2. What is the MOQ?

Sample order is acceptable, And some samples can be free.

3.Can I get a sample before mass production?

We can provide free sample if we have this in stock, as long as you afford the freight.if no stock, We can produce for you after get sample fee. lead time:5-7 business days.

4.How long do you need the delivery time?

(1)Supply within 5 -10 days (product in our Stock list)

(2)Custom products need to be calculated according to the quantity.

5.What 's your payment terms?

T/T, L/C at sight, Western Union.

6. How can we get your price ?

We need below information to quote for you:

1. Product Name

2. Standard

3. Material Grade (Chemical Composition)

4. Dimension

5. Quantity

6. The Drawing for Special Parts