Aluminum Coil 5000 Series Aluminum Pattern Plate

Aluminum Coil 5000 series representatives 5052 5005 5083,5754. The 5000 series aluminum alloy aluminum belong to the more commonly used series,the main elements for magnesium, with magnesium in the amount between 3-5%. And can be called aluminum magnesium alloy. Key features for low density, high tensile strength, elongation rate is high. In the same area under the weight of the magnesium alloy aluminum less than other series.

Ship board heatproof apparatus,material for interior and exterior of building,Parts of Electronic tools.Automobile Components.Excellent corrosion resistance andweld ability together with Easy to process and weld and superior hardness &heatproof Can be anodized for increased corrosion resistance.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | OTHERS | OTHERS | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | — | 0.05 | 0.03 | 0.03 | — | 99.5 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | — | 0.04 | 0.03 | 0.03 | — | 99.7 |

| 1100 | 0.95 Si + Fe | 0.05-0.20 | 0.05 | — | — | 0.1 | — | 0.05 | 0.15 | 99 | |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.30-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | — | — | 0.1 | — | 0.05 | 0.15 | Rem. |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | — | 0.25 | — | 0.05 | 0.15 | Rem. |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.20-0.6 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | Rem. |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50-1.1 | 0.1 | 0.25 | — | 0.05 | 0.15 | Rem. |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | — | 0.05 | 0.15 | Rem. |

| 5252 | 0.08 | 0.1 | 0.1 | 0.1 | 2.2-2.8 | — | 0.05 | — | 0.03 | 0.1 | Rem. |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Rem. |

| Alloy | Temper | Tensile Strength | Yield Strength | Elongation (%) | Tensile Strength | Yield Strength | |

| (ksi) | (ksi) | 0.01-0.05 in | 0.051-0.125 in | (MPa) | (MPa) | ||

| 1100 | H12 | 16 | 15 | 4 | 12 | 110.3 | 103.4 |

| H14 | 18 | 17 | 3 | 10 | 124.1 | 117.2 | |

| 3003 | H12 | 19 | 18 | 9 | 11 | 131 | 124.1 |

| H14 | 22 | 21 | 3 | 7 | 151.7 | 144.8 | |

| 3004 | H32 | 31 | 25 | 6 | 15 | 213.7 | 172.4 |

| H34 | 35 | 29 | 5 | 10 | 241.3 | 199.9 | |

| 3005 | H12 | 26 | 24 | 5 | 13 | 179.3 | 165.5 |

| H14 | 29 | 28 | 4 | 9 | 199.9 | 193.1 | |

| 5005 | H12 | 20 | 19 | 5 | 9 | 137.9 | 131 |

| H14 | 23 | 22 | 4 | 7 | 158.6 | 151.7 | |

| 5052 | H32 | 33 | 28 | 7 | 10 | 227.5 | 193.1 |

| H34 | 38 | 31 | 6 | 8 | 262 | 213.7 | |

| 5056 | O | 42 | 22 | 23 | 24 | 289.6 | 151.7 |

| H38 | 60 | 50 | 6 | 13 | 413.7 | 344.7 | |

| 6061 | T4 | 35 | 21 | 22 | 24 | 241.3 | 144.8 |

| T6 | 45 | 40 | 12 | 17 | 310.3 | 275.8 | |

| 7075 | O | 33 | 15 | 16 | 18 | 227.5 | 103.4 |

| T6 | 83 | 73 | 11 | 12 | 572.3 | 503.3 | |

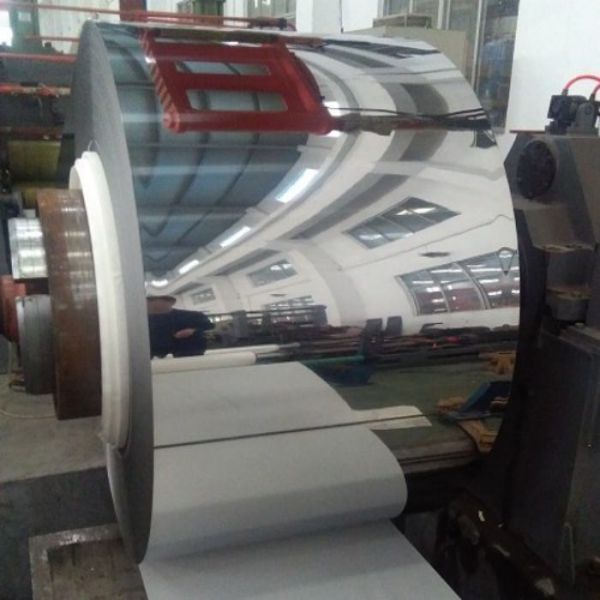

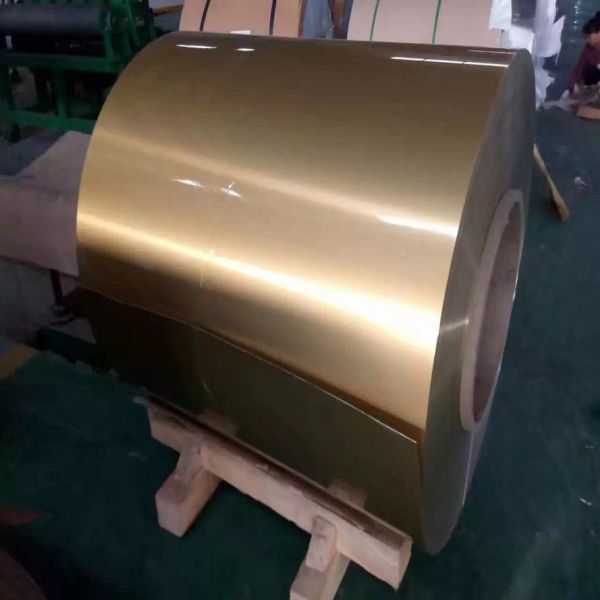

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, picking or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry,Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treament after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building construction. |

| NO.1 | The surface finished by heat treament and picking or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

(1): High quality aluminum products with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.