Aluminum Foil Aluminium Alloy Embossed Sheet

Aluminum foil, also known as aluminum foil, commonly known as tin foil paper, tin paper, etc., is a tool made of flattened metal aluminum. It is mainly used for cooking and holding food in the kitchen, or for making materials that can be easily cleaned. Thousands of tons of aluminum foil paper are used around the world to protect and package food, cosmetics and chemicals. Most aluminum foil paper is shiny on one side and gray on the other. Aluminum foil paper for food can wrap food on both sides. It is usually recommended to wrap it in bright bread to improve the heat transfer effect.

Aluminum foil is a rolled aluminum product with a thickness of less than 0.20mm and a rectangular and uniform cross section. Including capacitor aluminum foil, hydrophilic aluminum foil and composite aluminum foil. Because of its excellent characteristics, it is widely used in food, beverage, cigarette, medicine, photographic base plate, household daily necessities, etc., and is usually used as its packaging material; Electrolytic capacitor materials; Thermal insulation materials for buildings, vehicles, ships, houses, etc; It can also be used as decorative gold and silver thread, wallpaper, various stationery prints and decoration trademarks of light industrial products. Among the various uses mentioned above, the aluminum foil can most effectively exert its performance point as a packaging material. Aluminum foil is a soft metal film, which not only has the advantages of moisture-proof, air tight, light shielding, abrasion resistance, fragrance protection, non-toxic and tasteless, but also is easy to process beautiful patterns and patterns of various colors because of its elegant silver white luster. In particular, after the aluminum foil is compounded with plastic and paper, the shielding property of aluminum foil is integrated with the strength of paper and the heat sealing property of plastic, which further improves the shielding property of water vapor, air, ultraviolet and bacteria necessary for packaging materials, and greatly expands the application market of aluminum foil. Since the packaged goods are fully isolated from the light, humidity and air, the packaged goods are well protected. Especially for the packaging of cooked food, the use of this composite aluminum foil material can ensure that the food will not deteriorate for at least one year. Moreover, heating and unpacking are very convenient, and they are very popular with consumers.

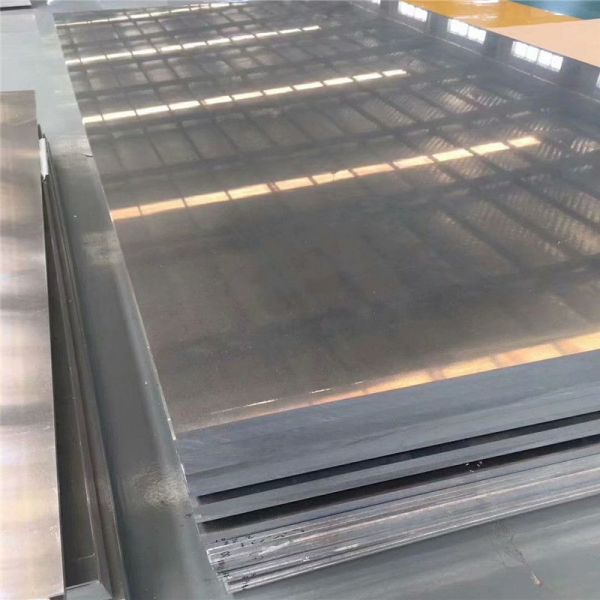

| Alloy | Temper | Thickness | Width | Embossed Depth | Length |

| 1050 | O/H14/H22/H24/H32 | 0.3mm-3mm | 300mm-1500mm | Customized | As Required |

| 1060 | O/H14/H22/H24/H32 | 0.3mm-3mm | 300mm-1500mm | Customized | As Required |

| 1100 | O/H14/H22/H24/H32 | 0.3mm-3mm | 300mm-1500mm | Customized | As Required |

| 3003 | O/H14/H22/H24/H32 | 0.3mm-3mm | 300mm-1500mm | Customized | As Required |

| 5052 | O/H14/H22/H24/H32 | 0.3mm-3mm | 300mm-1500mm | Customized | As Required |

By Thickness

Aluminum foil can be divided into thick foil, single zero foil and double zero foil according to the thickness difference.

① Thick foil: foil with thickness of 0.1-0.2mm.

② Single zero foil: foil with thickness of 0.01mm and less than 0.1mm/.

③ Double zero foil: the so-called double zero foil refers to the foil with two zeros after the decimal point when its thickness is measured in mm, usually the aluminum foil with a thickness less than 0.01, that is, the aluminum foil with a thickness of 0.005 ~ 0.009mm. When expressed in English, thick foil is called "heavy gauge foil ', single zero foil is called "medium gauge foil", and double zero foil is called "light gauge foil". In foreign countries, aluminum foil with thickness ≤ 40ltm is sometimes called light gauge foil, while aluminum foil with thickness > 40btm is collectively called heavy gauge foil.

By Surface

Aluminum foil can be divided into one side light aluminum foil and two side light aluminum foil according to the surface state.

① Single side light aluminum foil: double rolled aluminum foil, after being rolled, one side is bright and the other side is dark. Such aluminum foil is called one side light aluminum foil. The thickness of the aluminum foil on one side is generally not more than 0.025 mm.

② Double sided light aluminum foil: a single rolled aluminum foil, with two pictures in contact with the roll. The two sides of the aluminum foil are divided into mirror two sided light aluminum foil and ordinary two sided light aluminum foil due to the different surface roughness of the roll. The thickness of the two-sided polished aluminum foil is generally not less than 0.01mm.

By Status

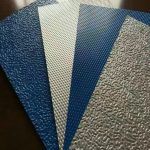

Aluminum foil can be divided into plain foil, embossed foil, composite foil, coated foil, colored aluminum foil and printed aluminum foil according to the added state.

Aluminum foil. Haodian Technology

Aluminum foil. Haodian Technology

① Plain foil: aluminum foil without any other processing after rolling, also known as light foil.

② Embossed foil: aluminum foil with various patterns pressed on the surface.

③ Composite foil: composite aluminum foil formed by laminating aluminum foil with paper, plastic film and paperboard.

④ Coated foil: aluminum foil coated with various resins or paints.

⑤ Colored aluminum foil: aluminum foil coated with a single color on the surface.

⑥ Printed aluminum foil: aluminum foil that forms various patterns, patterns, characters or pictures on the surface by printing. It can be one color, up to 12 colors.Soft aluminum foil can also be further pressed into four zero foil for high-end decoration.

By Application

Aluminum foil is mainly divided into packaging aluminum foil (food and drug packaging), decorative aluminum foil, electromechanical equipment aluminum foil (transformer aluminum foil), beer sealing foil, cigarette foil, household aluminum foil, etc.