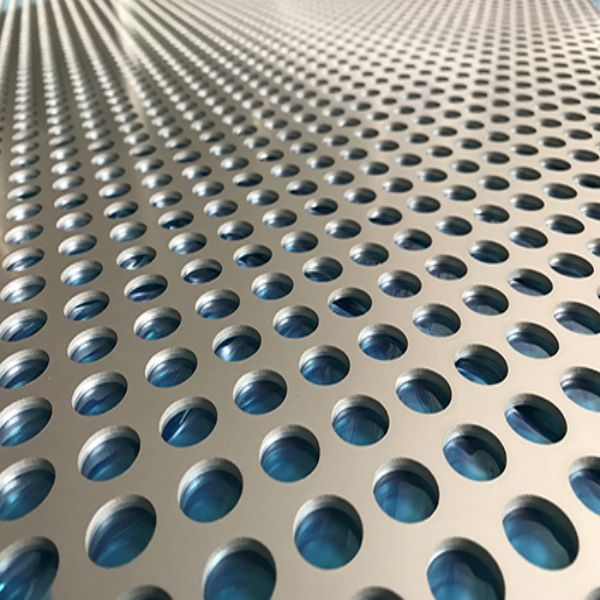

Aluminum perforated sheet 1100

Aluminum perforated sheet:1100 aluminium is one of the representatives of 1 series pure aluminium strip, which is used for industry, its strength is relatively low, and it has excellent ductility, formability, weldability and corrosion resistance; after anodizing, it can further improve the corrosion resistance and at the same time obtain a beautiful surface; but can not be strengthened by heat treatment. Meanwhile, with the addition of a small part of the alloy component Cu, the processability and surface processing of 1100 aluminium and other alloy characteristics are enhanced, which can be better used for large storage tanks, food and chemical handling and storage equipment, sheet metal products, welding assemblies, reflectors, nameplates, and more.

| Chemical Composition | ||||||||

| Alloy | Si | Fe | Cu | Mn | Zn | Other | Aluminum | |

| Each | Total | |||||||

| 1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 0.05 | 0.15 | Min 99 | |

| Mechanical Properties | ||||

|

Temper |

Specifications | Tensile Strength | Yield Strength | Elongation |

| Thickness(in.) | (ksi) | (ksi) | (%) | |

| 1100-O

(annealed) |

0.006-0.019 | 11.0-15.5 | Min 3.5 | Min 15 |

| 0.020-0.031 | Min 20 | |||

| 0.032-0.050 | Min 25 | |||

| 0.051-0.249 | Min 30 | |||

| 0.250-3.000 | Min 28 | |||

| 1100-H12/

1100-H22 |

0.017-0.019 | 14.0-19.0 | Min 11.0 | Min 3 |

| 0.020-0.031 | Min 4 | |||

| 0.032-0.050 | Min 6 | |||

| 0.051-0.113 | Min 8 | |||

| 0.114-0.499 | Min 9 | |||

| 0.500-2.000 | Min 12 | |||

| 1100-H14/

1100-H24 |

0.009-0.012 | 16.0-21.0 | Min 14.0 | Min 1 |

| 0.013-0.019 | Min 2 | |||

| 0.020-0.031 | Min 3 | |||

| 0.032-0.050 | Min 4 | |||

| 0.051-0.113 | Min 5 | |||

| 0.114-0.499 | Min 6 | |||

| 0.500-1.000 | Min 10 | |||

| 1100-H16/

1100-H26 |

0.006-0.019 | 19.0-24.0 | Min 17.0 | Min 1 |

| 0.020-0.031 | Min 2 | |||

| 0.032-0.050 | Min 3 | |||

| 0.051-0.162 | Min 4 | |||

| 1100-H18/

1100-H28 |

0.006-0.019 | Min 22.0 | - | Min 1 |

| 0.020-0.031 | Min 2 | |||

| 0.032-0.050 | Min 3 | |||

| 0.051-0.128 | Min 4 | |||

| 1100-H112 | 0.025-0.499 | Min 13.0 | Min 7.0 | Min 9 |

| 0.500-2.000 | Min 12.0 | Min 5.0 | Min 14 | |

| 2.001-3.000 | Min 11.5 | Min 4.0 | Min 20 | |

Over 99% content of aluminum, 1100 aluminum perforated sheet is soft and has low strength, so it is not suitable for high-strength, high-pressure or hardness applications, instead, it is used for chemical equipment, decorative trim and heat exchangers.

1100 aluminum perforated sheet has superior correction resistance, formability, conductivity and high weld-ability, so it is best used for welding, brazing and soldering but has poor machine-ability. For the features above, 1100 aluminum perforated sheet is available for various applications, including chemical storage and processing equipment.

1100 aluminum perforated sheet is nonmagnetic and non-heat treatable, besides, it has great finishing capacity, so it can be a wise choice for decorative applications.