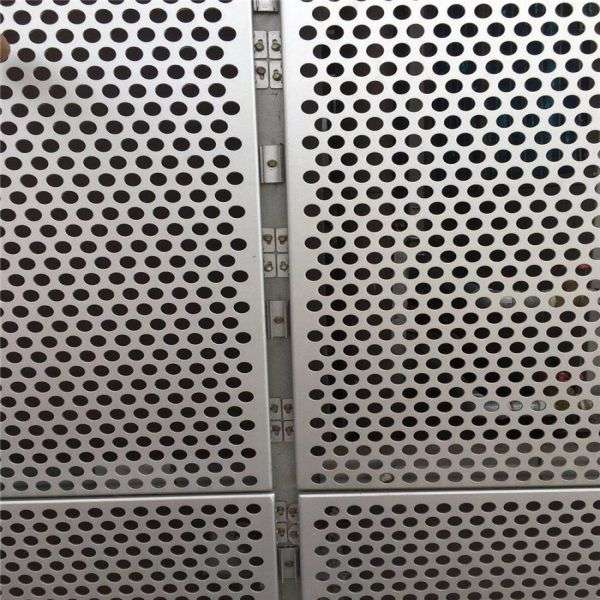

Aluminum perforated steel plate 7075

7075 Aluminum perforated steel plate:7075 aluminum alloy belongs to Al-Zn-Mg-Cu superduralumin, which is a cold-treated forging alloy with high strength and hardness, far better than soft steel. Due to the fine grain structure inside 7075 aluminum alloy, it has excellent deep drilling performance, enhanced wear resistance of tools, good mechanical properties and anode reaction.

7075 Aluminum perforated steel plate:7075 aluminum alloy with extremely high strength and anti-exfoliation corrosion and stress corrosion fracture resistance. Good plasticity after solid solution treatment, good strengthening effect of heat treatment, good strength under 150℃ and especially good low-temperature strength. After eliminating the stress, the processed 7075 aluminum alloy will not be deformed or warped.

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Contents | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | 0.1 | 0.15 | balance |

| Name: | perforated mesh /perforated sheet /punching mesh /decorative mesh |

| Material : | Aluminum sheet ,steel sheet ,galvanized sheet ,carbon steel ,copper nickel ,titanium ect. |

| Surface finish : | 1.For aluminum mater mill finish :

Anodized finish (silver only )powder coated (any color ) PVDF (any color ,smoother surface and longer life span) 2.For iron steel material galvanized:electric galvanized ,hot-dip galvanized ,powder coated |

| Sheet size(m): | 1x1m ,1x2m ,1.2x2.4m ,1.22x2.44m ,ect . |

| Thickness(mm) : | 0.3mm-10mm |

| Hole shape : | round ,square ,diamond ,hexagonal ,star ,flower ,ect . |

| Perforation way : | Straight perforation ,staggered perforation . |

7075 is mainly used for manufacturing aircraft structures and other high-stress structural parts with high strength and corrosion resistance. Such as on the plane, under the wing panel, truss, etc. After solid solution treatment, the plasticity is good, the heat treatment strengthening effect is good, has the good strength below 150 degrees, and has the particularly good low temperature strength, Poor welding performance, stress corrosion cracking tendency.

Widely used in mold processing, mechanical equipment, fixtures, aerospace industry, blow molding (bottle) mold, ultrasonic plastic welding mold, golf head, shoe mold, paper mold, foam molding mold, wax mold, mechanical equipment, used in the production of high-end aluminum bicycle frame.

1. How about the delivery time?

Usually within 15- 20 days, customized order may need longer time.

2.Can you offer free sample?

Yes, but usually the customer need to pay the freight, We'll send back the courier charge if you make an order.

3.Can I have your products with my own logo on it?

Yes! Accept any custom logos, just send us your design in pdf. ai, or high res jpg. We would send you layout art with your logo on our products to check. The setup cost would be quoted per artwork.

4.Can the surface of the perforated sheet be plastic coated?

No problem.At your request, please feel free to choose.However, such products will increase the cost.

5.Is the opening whatever we want?

Generally speaking, the use of circular hole is the largest, rectangular and diamond-shaped hole are also very popular. If you have special requirements, please contact us in a timely manner.

6.What is artistic perforated metal screen?

Artistic perforated metal mesh, unlike ordinary sheet metal processing methods, it is made within the framework of special stamping, forming special tricks, text, graphics and so on. Style can be customized according to your needs.