Aluminum plate titanium alloy high strength 6005

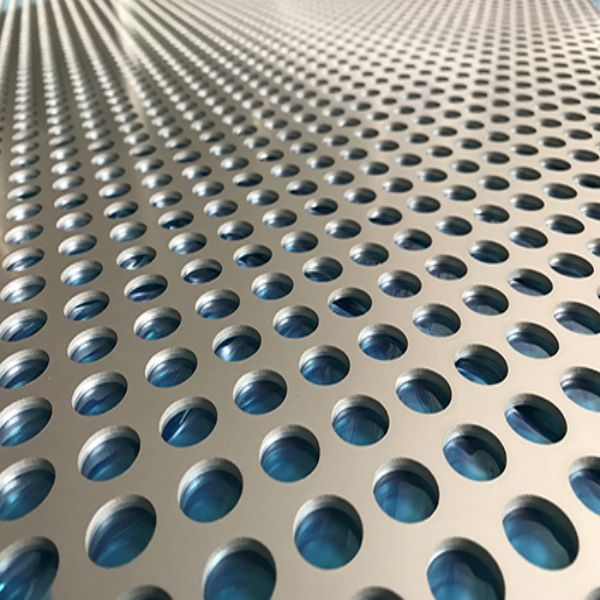

Aluminum plate titanium alloy high strength 6005:High strength, especially anti-fatigue strength. High plasticity and corrosion resistance, can not be strengthened by heat treatment. The plasticity is good during semi-cold work hardening, the plasticity is low when cold work hardening, the machinability is poor, and Titanium alloy 6005 high strength aluminum plate can be polished. Good cold work ability.

Titanium alloy 6005 high strength aluminum plate has similar properties to 6106 and 6082 alloys and is sometimes interchangeable, but 6005 / 6005A has better extrusion properties.

6005-T5 has the same minimum tensile strength and yield strength as 6061-T6, and has better machinability and strength properties than 6063-T6.

The welding performance similar to 5182 aluminum plate , but the welding performance of 6005 aluminum sheet by gas welding, argon arc welding, spot welding and roll welding is very good.

| Chemicai Composition(WT%) | |||||||||

| Grade | (Si) | (Cu) | (Mg) | (Zn) | (Mn) | (Ti) | (Cr) | (Fe) | (Al) |

| 6005 | 0.6-0.9 | ≤0.1 | 0.4-0.6 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.35 | Balance |

| Usages | |||||||||

| 6005 aluminum alloy was widely used at the time to knead the profiles and pipes of ladders, wheelchairs, TV antennas, stands and other products, but it should be noted that 6005 alloys cannot be used to make shock-resistant structures. 6005 aluminum sheet can also be used for hand rail tubing; truck, trailer, automotive, bus, and rail components; platforms, ladders, structures; building and construction applications; marine applications. | |||||||||

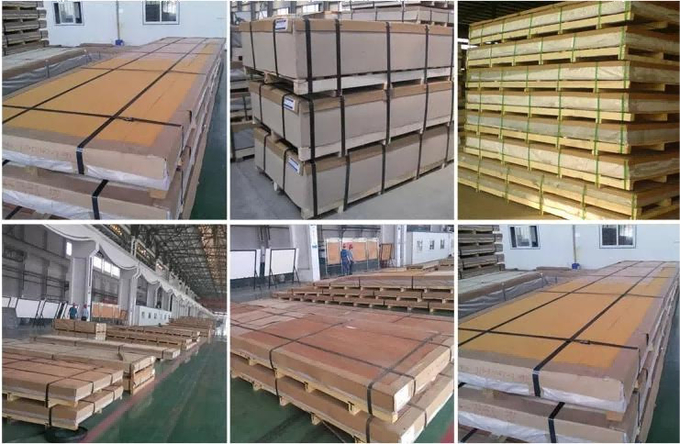

Export fumigated wooden frame or wooden case packing.

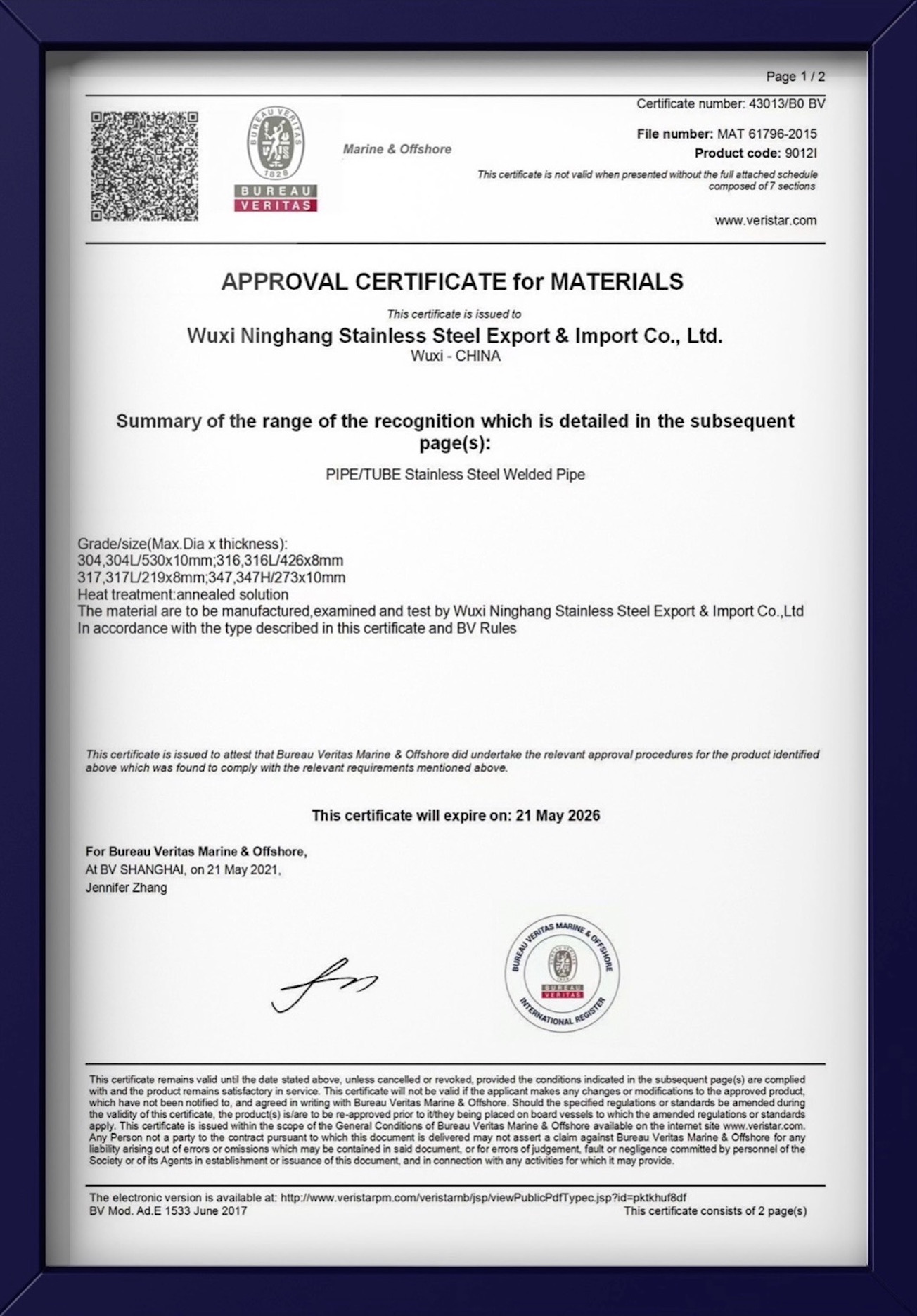

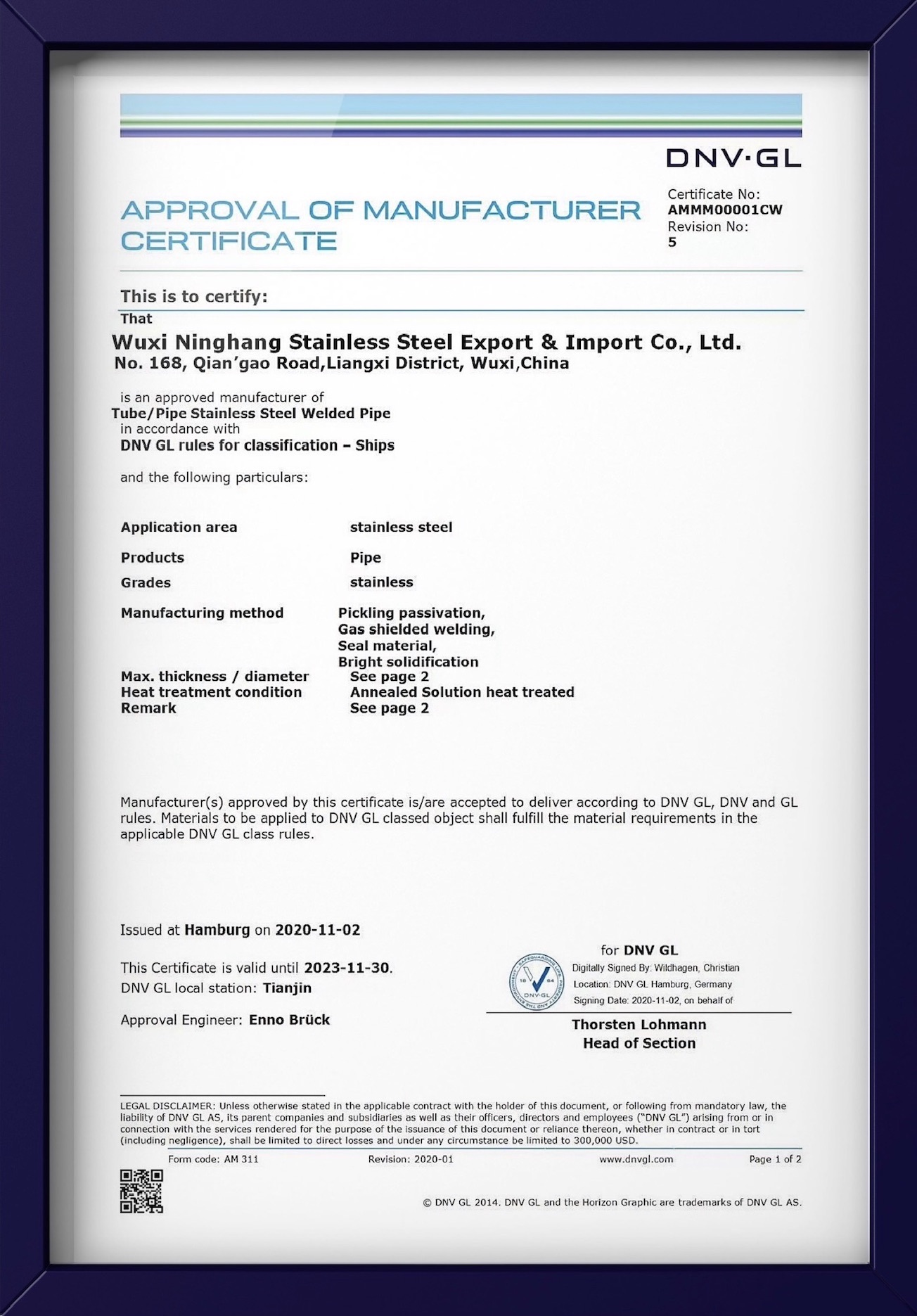

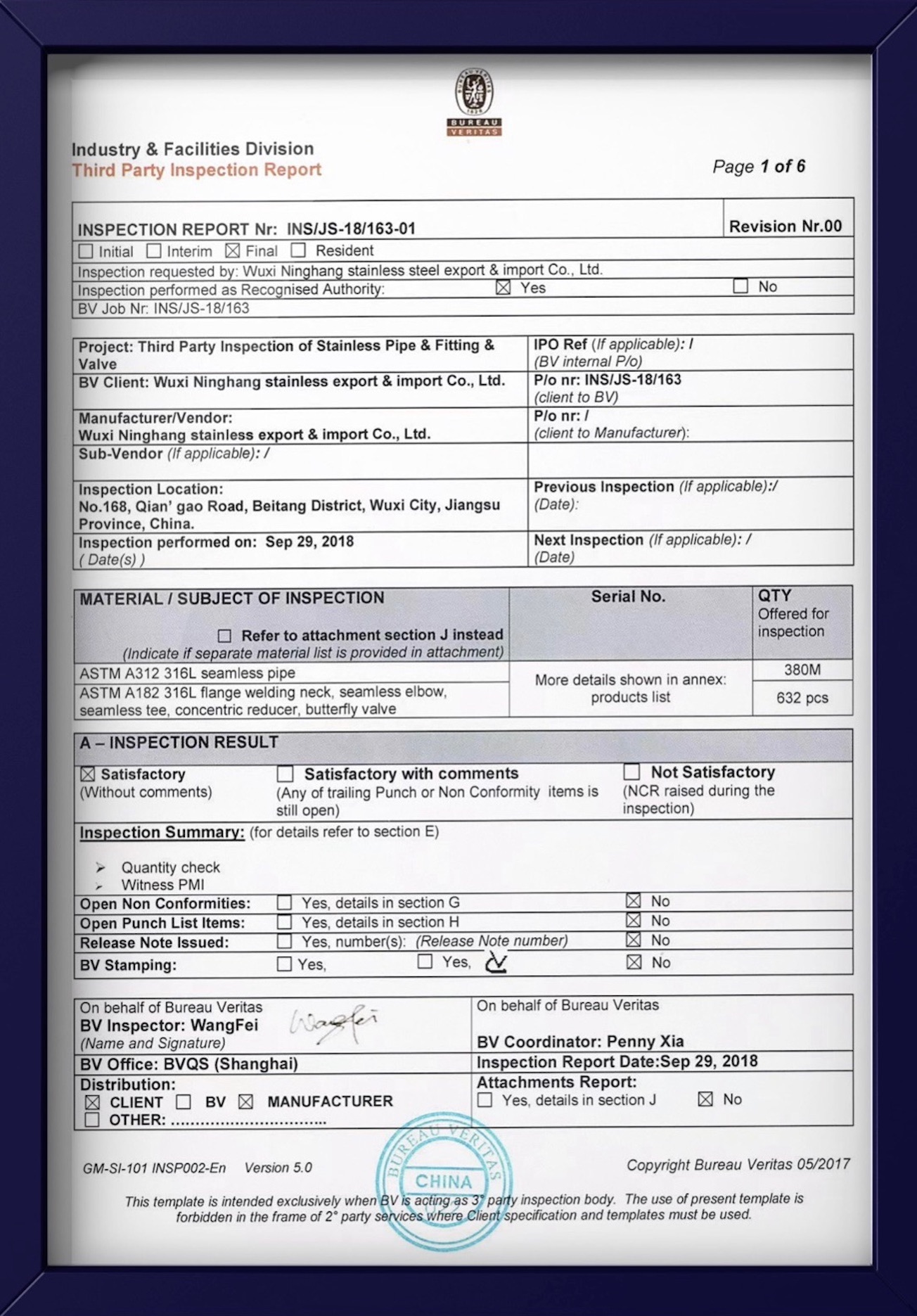

1.:How do we trust your company?

We specialise in steel production and sales for more than ten years as golden supplier,headquarters locates in WUXI, JIANGSU Province, you are welcome to investigate in any ways.

2. How can we guarantee quality?

(1)We can provide samples for free.We can send the samples by TNT,DHL,FEDEX,EMS,UPS or to your warehouse.

(2)Always a pre-production sample before mass production.

(3)Always final Inspection before shipment.

3.Do you have products in stock?

There are 10000 tons stock for various size.plsease inform us what model you need, we will send stock details to you.

4.How long will it take to produce my order?

Our normal produce time is 7-25 working days,depend on your order.

5.How much will the shipping cost be?

This will depend on the size and weight of your order and the method of shipping.

6.Can you help me find the shipping company?

Of course, if you don't work with a shipping company.We have a long-term cooperation of the transport team can provide you with lower prices, better service.

7. Will our goods be damaged during the long-distance transport? How to avoid it?

No damage, we will affix a low viscosity protective film on the surface of the product, effectively avoid scratches, easy to uncover when using, and will not leave stains on the surface.For long distance transportation we have professional experience,familiar with the packaging and arrangement of the goods, let the goods safely arrive at your destination.

8. Why should you buy from us not from other suppliers?

(1)Source manufacturers, leading equipment, excellent team skills.

(2)Low price, fast delivery and excellent quality, good service.

(3)Professional technical solution.