Aluminum Sheet 5052

5052 belongs to the Al-Mg alloy, which is widely used, especially in the construction industry, and is the most promising alloy. Aluminum sheet 5052 is always called Marine grade aluminum sheet. Because it has a very good quality of corrosion resistance, and very good performance of welding, so many customers use this alloy for ship building, like 5052 H32 is always used for small boat building. In addition, it has good cold workability, and moderate strength. It is used to manufacture aircraft fuel tanks, fuel pipes, metal parts for transportation vehicles and ships, instruments, street lamp brackets and rivets, hardware products, electrical enclosures, etc.

| Chemicai Composition(WT%) | ||||||||

| Grade | (Si) | (Cu) | (Mg) | (Zn) | (Mn) | (Cr) | Fe | (Al) |

| 5052 | ≤0.25 | ≤0.1 | 2.2-2.8 | ≤0.1 | ≤0.1 | 0.15-0.35 | ≤0.4 | Balance |

| Physical specification(min) | ||||||

| Temper | Density (kg/m3) | Thickness (mm) | σ0.2/MPa | σb/MPa | δ/% | HB |

| O | 2.66 | 0.5-0.8 | 65 | 170-215 | 15 | 47 |

| 0.8-1.3 | 17 | |||||

| 1.3-6.5 | 19 | |||||

| 6.5-10.0 | 18 | |||||

| H12/H22/H32 | 0.5-1.3 | 160 | 215-265 | 5 | 60 | |

| 1.3-4.5 | 7 | |||||

| H14/H24/H34 | 0.5-0.8 | 180 | 235-285 | 3 | 68 | |

| 0.8-1.3 | 4 | |||||

| 1.3-4.5 | 6 | |||||

| H16/H26/H36 | 0.5-0.8 | 200 | 255-305 | 3 | 73 | |

| 0.8-4.5 | 4 | |||||

| H18/H38 | 0.5-0.8 | 220 | 270 | 3 | 77 | |

| 0.8-4.5 | 4 | |||||

| H112 | 4.5-6.5 | 110 | 195 | 9 | 52 | |

| 6.5-12.5 | 7 | |||||

| 12.5-40.0 | 65 | 175 | 10 | |||

| 40.0-80.0 | 14 | |||||

Widely used in shipbuilding, automobile, bridge, construction, machinery, pressure vessel and other manufacturing industries.liner, barrels, iron ladders and various shapes of stamping parts.

1.What are our main products?

We main products include Aluminum coil, sheet, round bar strip etc. All different styles of etched and embossed,surface finished will be customized.

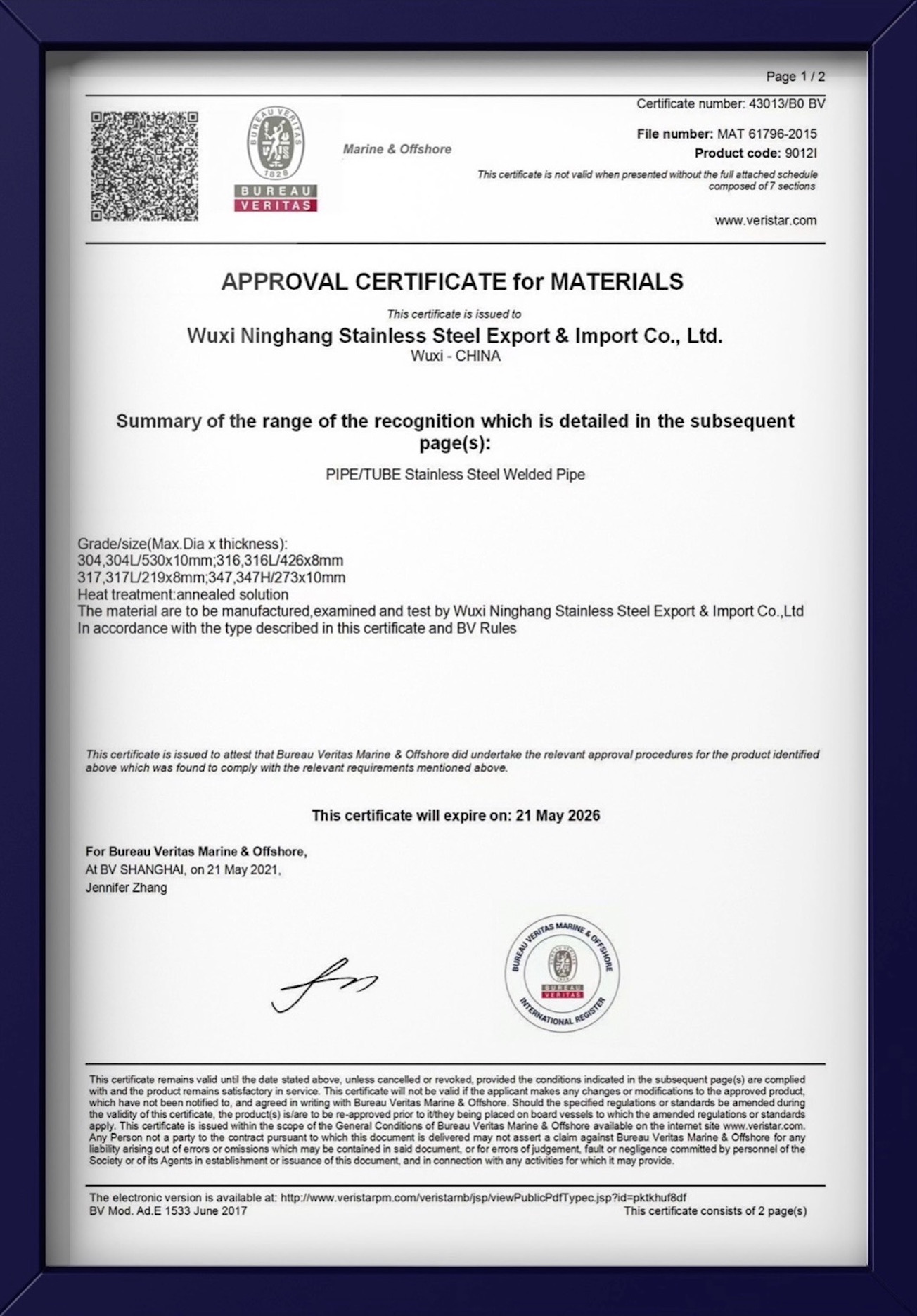

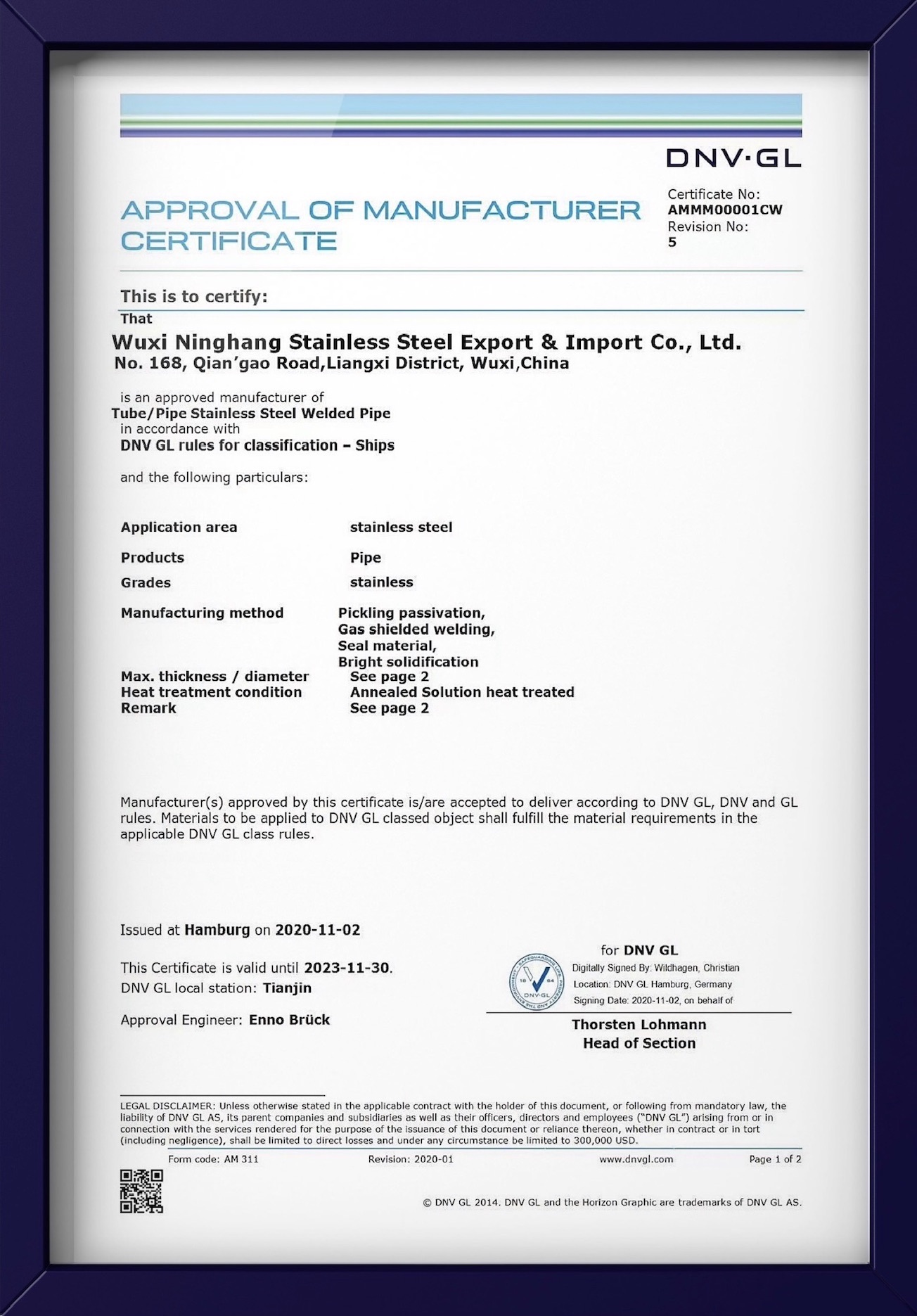

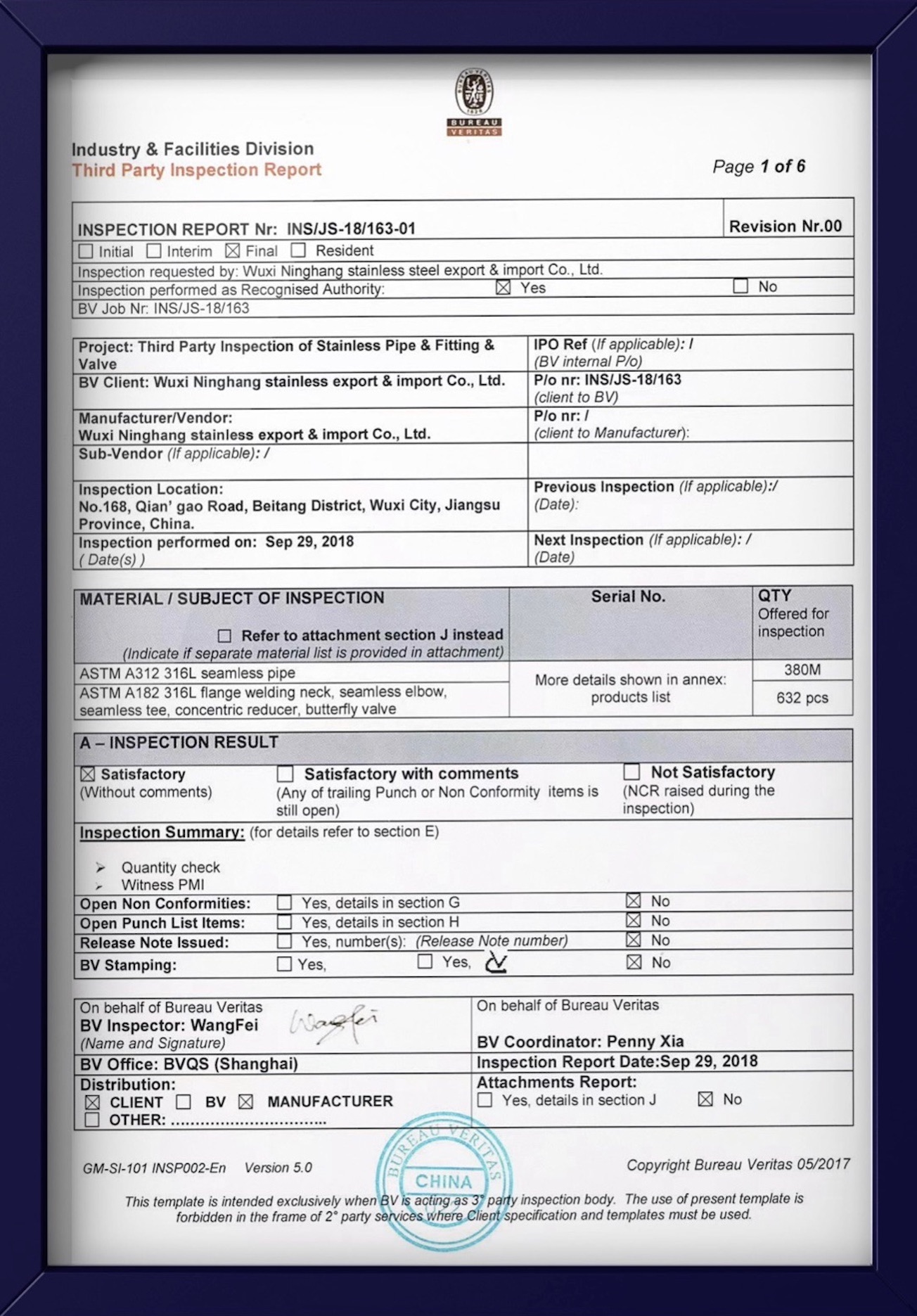

2..How can you ensure the quality of your product?

All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing. Mill Test Certification is supplied with shipment, Third Party Inspection is available.

3.What is your delivery time and the supply ability?

The delivery time normally within 15~20working days,we can supply about 15,000tons every month.

4.What kind of equipment in your factory?

Our factory have advanced five-eighth roller rolling,cold rolling production equipment on the roll,advanced processing and testing equipment,which makes our product better quality with efficiency.

5.About the complaint,quality problem,etc aftersales service,how do you handle it?

We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.

6.Can you provide sample ?

Small samples in store and can provide the samples for free.

Customized samples will take about 5-7days.