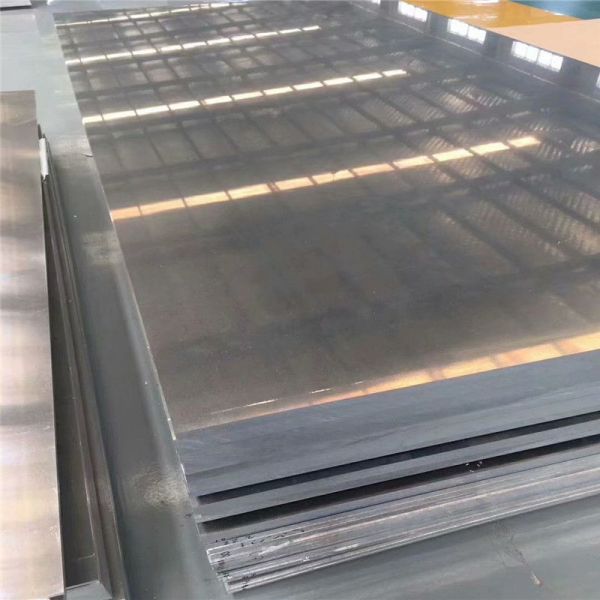

Anodized Aluminum Sheet 1070

Anodized Aluminum Sheet 1070:1070A aluminum plate is industrial pure aluminum. Industrial pure aluminum has the general characteristics of aluminum, such as low density, good conductivity and thermal conductivity, good corrosion resistance and good plastic processing performance. It can be processed into plates, strips, foils and extruded products, and can be used for gas welding, argon arc welding and spot welding. Industrial pure aluminum cannot be strengthened by heat treatment, but Anodized Aluminum Sheet 1070 is strength can be improved by cold deformation. The only heat treatment form is annealing.

Performance

High conductivity: The conductivity of 1070 aluminum sheet can reach 62, its thermal conductivity and electrical conductivity is second only to copper, silver, and gold.

Lightweight: At the same volume, 1070 aluminum is lighter than steel, iron, and copper.

Excellent corrosion resistance: The 1070 aluminum sheet has excellent corrosion resistance in most environments. Such as exposure to the atmosphere, immersion in water, most acids, organic compounds.

1070 aluminum sheet is a non-heat treated alloy that is cooled and processed to increase its strength.

Can accept contact welding and gas welding.

Aluminum alloy has a long service life, low cost, and high recovery value.

Heat Treatment Process

Complete annealing:Heating to 390 ~ 430 °C;Depending on the thickness of the material, the holding time should be controlled from 30 to 120 minutes;The temperature decreases at a rate of 30 ~ 50 °C/H. When the temperature of the furnace is cooled to 300 °C, then air-cooled.

Rapid annealing:Heating to 350 ~ 370 °C;Depending on the thickness of the material,the holding time should be 30 ~ 120 min, air or water cooling.

Quenching and aging:Quenching at 500 ~ 510 °C, air cooling;Artificial aging was 95 ~ 105 °C, 3H, air cooling;Natural aging-room temperature 120H.

| Chemicai Composition(WT%) | ||||||||

| Grade | (Si) | (Cu) | (Zn) | (Mn) | (Ti) | Fe | Others | (Al) |

| 1070 | ≤0.2 | ≤0.04 | ≤0.04 | ≤0.03 | ≤0.03 | ≤0.25 | ≤0.03 | 99.7 |

| Mechanical Properties | ||||||||

| yield strength(σ0.2 (MPa) | tensile strength(mpa) | |||||||

| ≥15 | ≥55 | |||||||

| Application | ||||||||

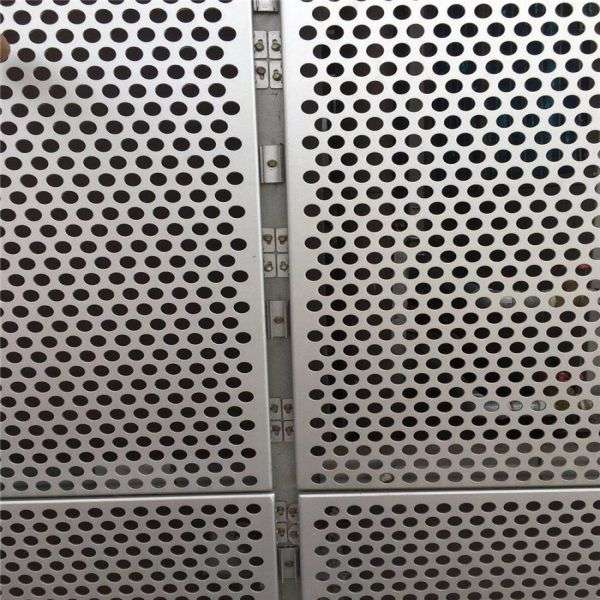

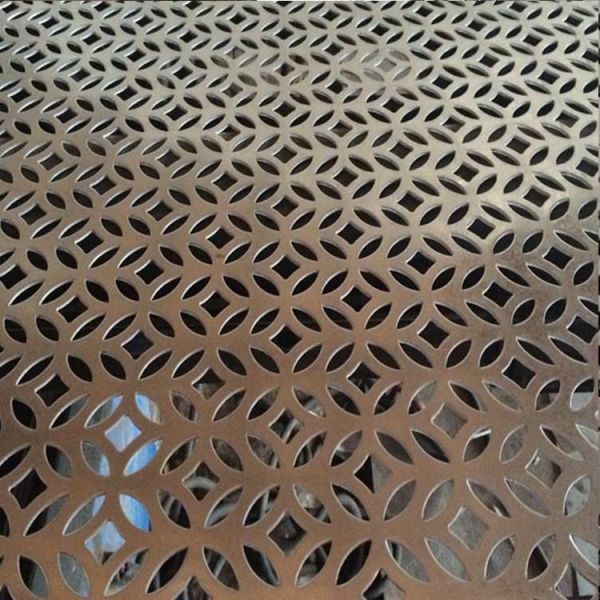

| It is widely used in products with low strength requirements, such as chemical instruments, thin plate processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surfaces and plates, nameplates, kitchenware, decorations, reflective appliances, etc. | ||||||||

(1): High quality aluminum products with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.