Anodized aluminum square rod 7050

7050 anodized aluminum square rod:7050 aluminum bar is the aluminum of the aerospace grade which has stress corrosion resistance, high strength as well as toughness. This alloy heat treatable and possess high mechanical properties as well as high fracture toughness. This alloy is available in the two tempers mainly T7451 as well as T7651. 7050 anodized aluminum square rod has good electrical conductivity. This alloy cannot be used for welding purpose as it weakens alloy.

| Standard | ASTM AISI, SUS, EN, JIS, DIN, GB ASME |

|

Other Material |

1060, 1050, 1070, 1100, 3003, 3004, 5052,5652, 5154, 5254, 5454, 5083, 5086,

5056,5456, 2024, 2014, 6061, 6063. etc |

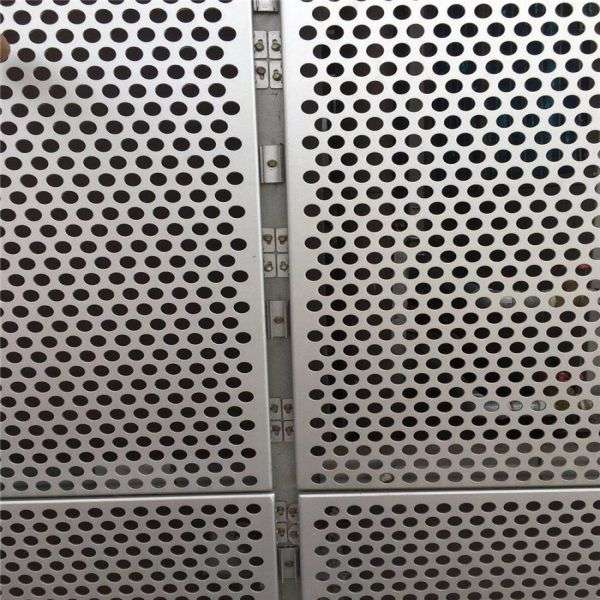

| Surface | Mill finish,polished,anodizing,brushing,sand blasting,powder coating,etc |

| Diameter | 2~800mm |

| Length | 1m,2m,3m,5.8m,6m,or as required |

|

Application |

1. Lighting ,solar reflector plate

2, architectural appearance 3, interior decoration: ceiling, metope, furniture, cabinets and so on 4.elevator ,automotive interior and exterior decoration 5. Interior decoration: such as photo frame 6, household appliances, refrigerator, microwave oven, audio equipment, etc. 7. Aerospace and military aspects, such as China's current large aircraft, the shenzhou spacecraft series, satellite, etc. 8, machinery parts processing, mold manufacturing 9, chemical/insulation pipeline coating |

| Payment terms | T/T, L/C, and Western Union |

| Price terms | FOB CIF CFR CNF etc |

| Package | Export standard package:bundled wooden box or be required; The inner size of container is below: (1)20footGP:5.8m(length)x2.13m(width)x2.18m(high)about24-26 CBM (2)40footGP:11.8m(length)x2.13m(width)x2.72m(high)about68 CBM |

| Delivery time | Normally according to the order quantity. |

| Contact | If you have any question free to contact me |

7000 series Aluminum alloys have been the preferred choice for aerospace and aircraft applications ever since the introduction of commercial aircraft building in the post WWII era. Offering designers very high strength, low manufacturing costs, and a low replacing risk, the 7xxx series are alloys of choice in applications where strength is the primary requirement.

Main Use

Aircraft structural parts. Used for medium and heavy plate extrusion, free forging and die forging. Common applications for 7050 aluminum plates include bulkheads and fuselage frames that require a cross-sectional thickness of between 2 and 6 inches. Another common application is for wing skin. Most applications of this metal are for thicknesses greater than 2 inches, which makes this metal an excellent choice.

Other Uses

It can also be applied to various molds, fixtures, mechanical equipment and high-end aluminum alloy bicycle frames.