Coated Aluminum Colored Channel Steel

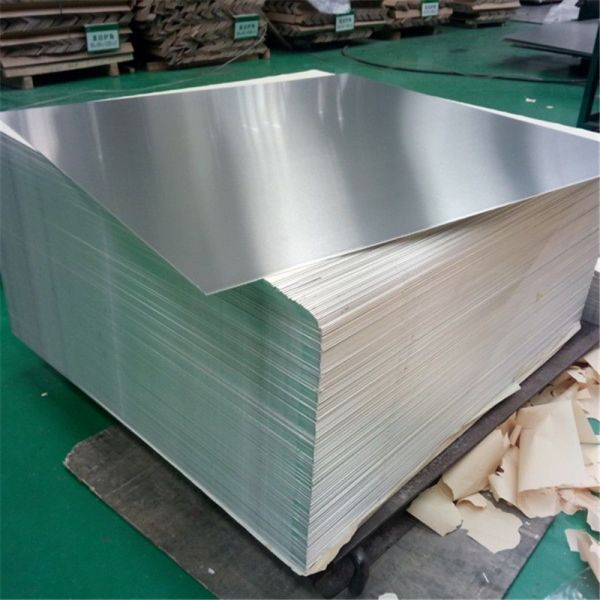

The main alloying elements of 6061 alloy are magnesium and silicon, and form Mg2Si phase. If it contains certain amount of manganese and chromium, it can neutralize the bad effect of iron.Sometimes a small amount of copper or zinc is added to enhance the strength of the alloy without significantly reducing its corrosion resistance. There is also a small amount of copper in the conductive material to offset the bad effects of titanium and iron on the conductivity. Zirconium or titanium can refine grain and control recrystallized structure. Lead and bismuth can be added to improve machinability.

In Mg2Si solid soluble in aluminum, the alloy has the function of artificial aging hardening. 6061 T651 is the main alloy, alloy 6061 is the pre-stretch heat treatment process of high quality aluminum alloy products, its strength is not compared with 2 or 7 XXX department system, but its more magnesium, silicon alloy properties, has the excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, high toughness and processing after deformation, dense material without defects and easy polishing, coloring film easily, good features such as oxidation excellent results.

| Product Name | Brushed Type Aluminum Coil |

| Folding Edge | Flat ( Triangle type, Arrow type are available.) |

| Material | 6000 Series Aluminum |

| Color | Silver/ Gold/ Rose Gold |

| Thickness | 0.6/0.8mm for standard/ Customized |

| Width | 20-1220mm |

| Length | 100M/Roll |

| MOQ | 10 Meters |

| Delivery time | 10-15 days |

| Waterproof | Yes |

| Advantage | Light, Easy to Assemble, Gloss Surface, Waterproof |

| 6000 Series Alloy (Generally called Al-Mg-Si Alloy, the Mg and Si are used as main alloy elements ) | |

| Alloy | 6061 6063 6082 |

| Temper | O F, etc. |

| Specification | Thickness≤170mm; Width≤2200mm ; Length≤12000mm |

| Application | Automotive, Aluminium For Aviation, Industrial Mould, Mechanical Components,

Transport Ship, Semiconductor Equipments, etc |

| Feature | Good corrosion resistant performance, well welding property, good oxidability,

easy to spray-finishing, well oxidation coloring, good machinability. |

1.Reply within 12 hours;

2.Free samples provided;

3.On-site production following-up;

4.Loading inspection with container fixing;

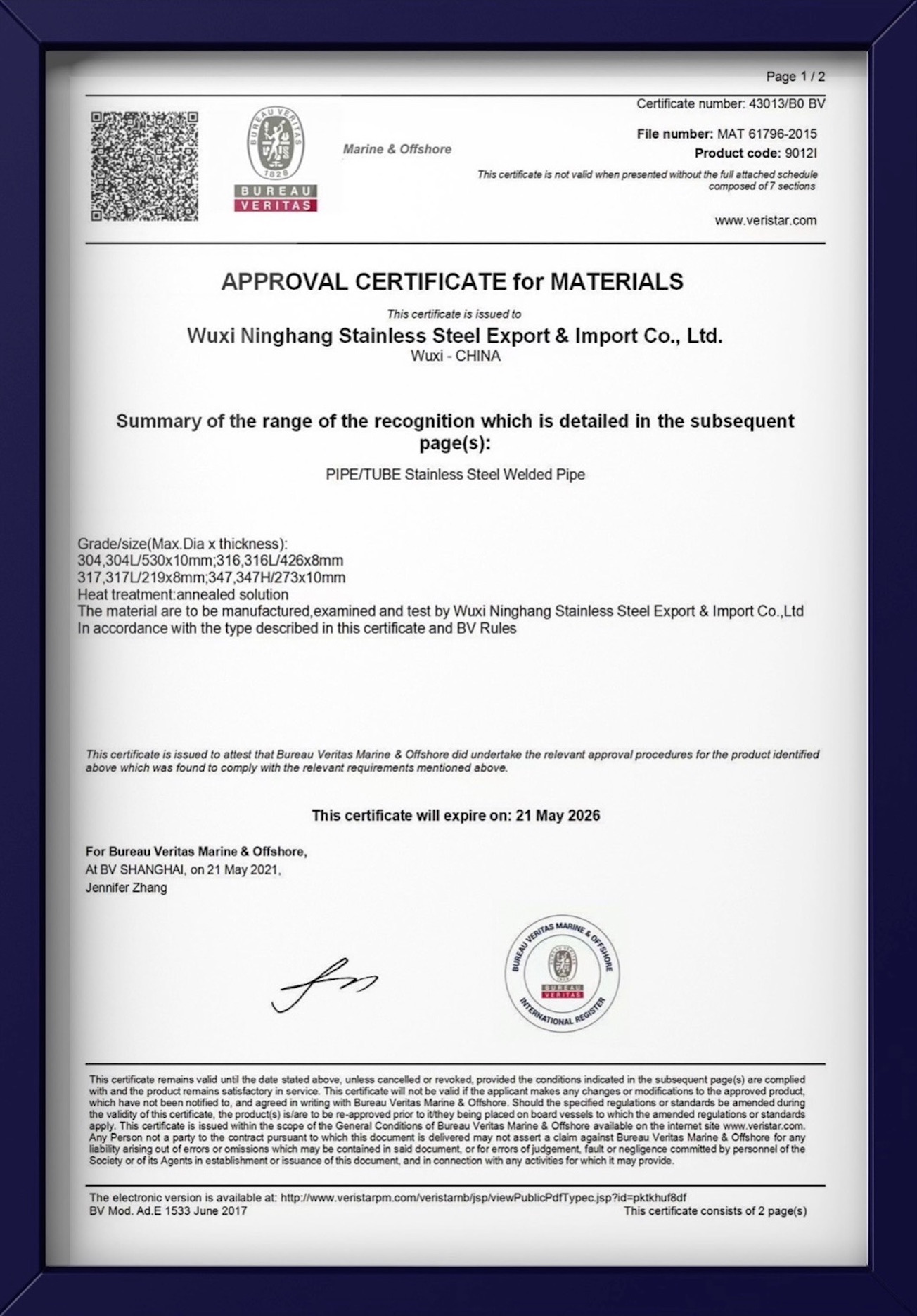

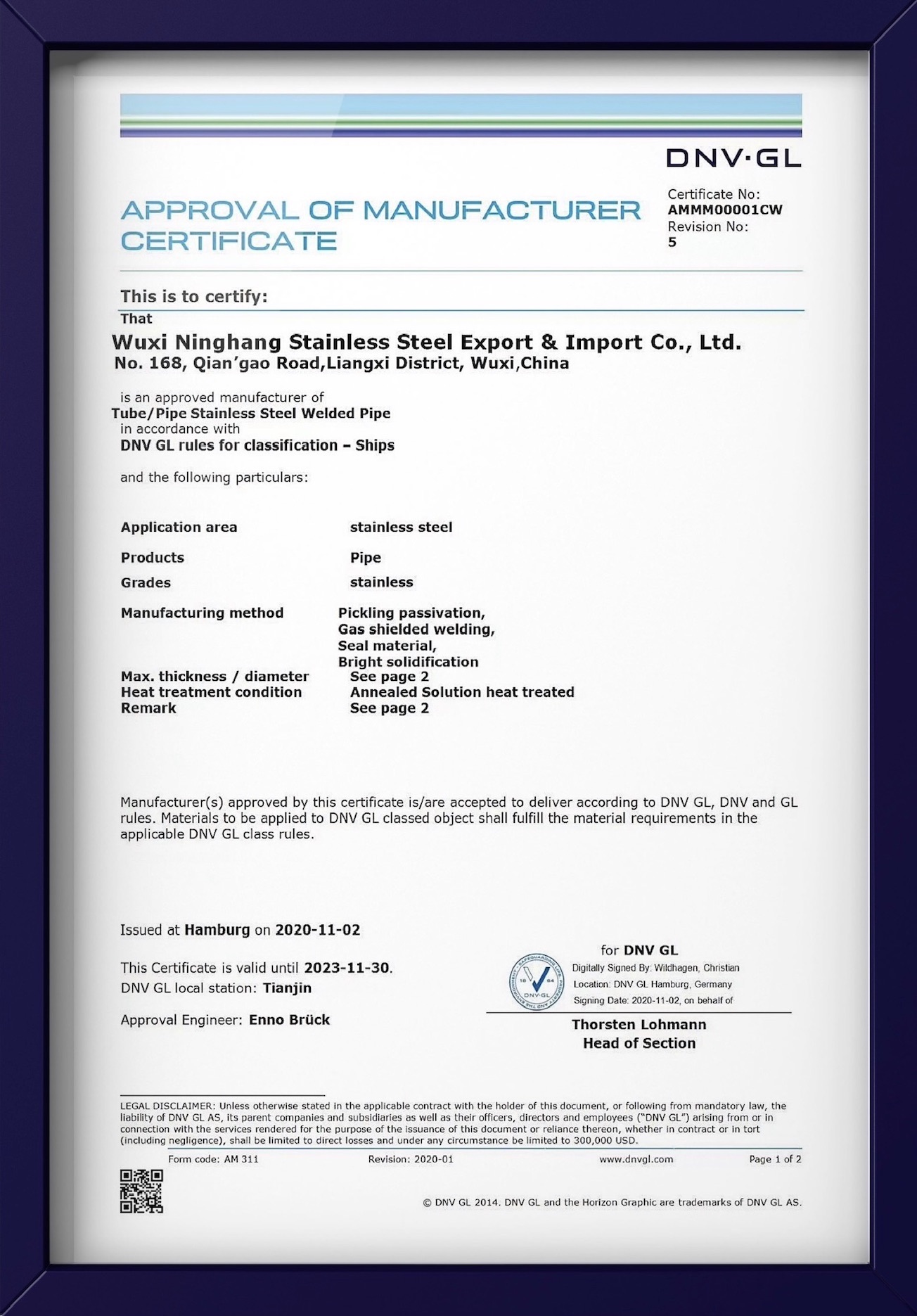

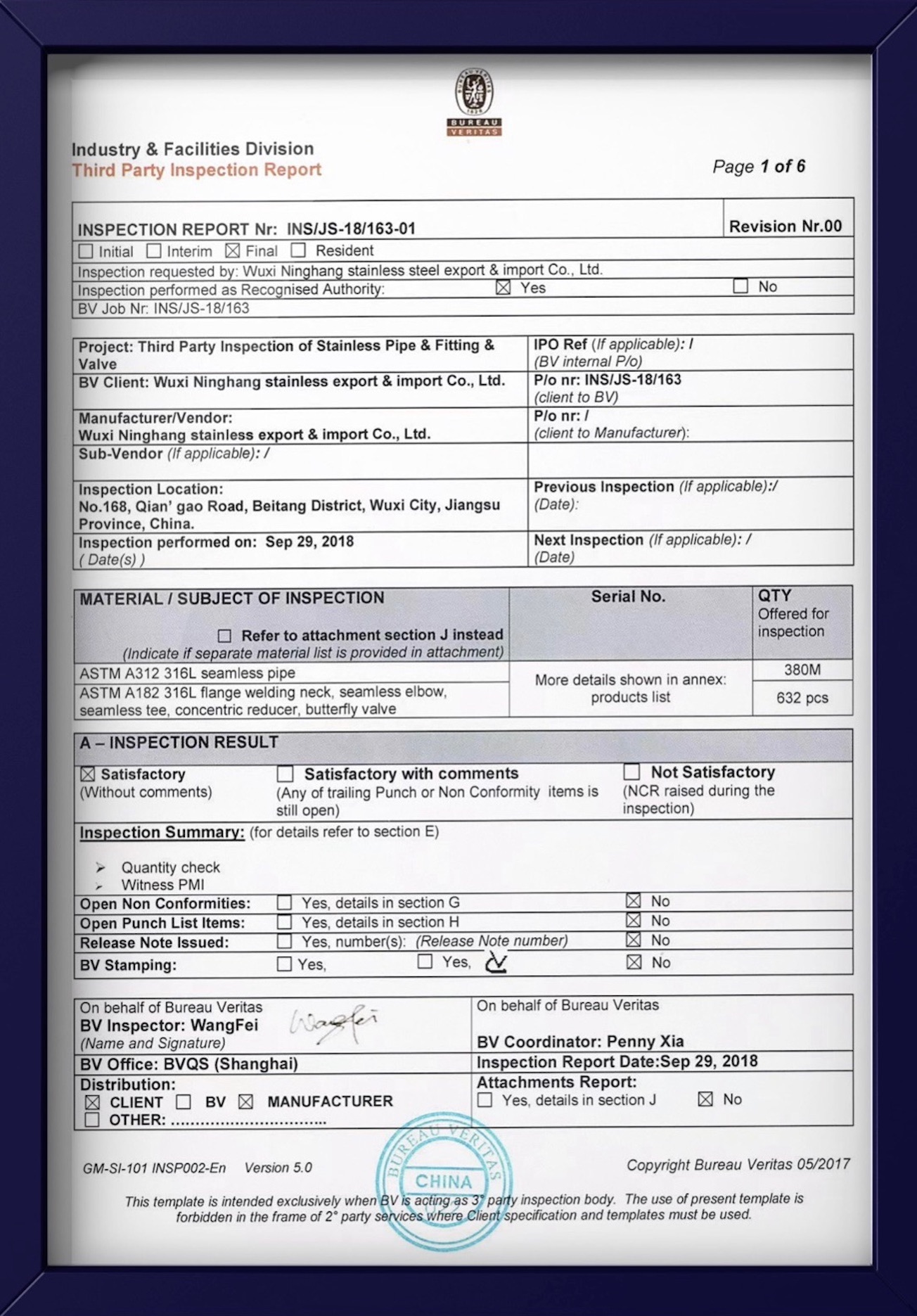

5.Third party inspection at your request;

6.Every employee of our company is the most professional and does their best to provide you with quality service.