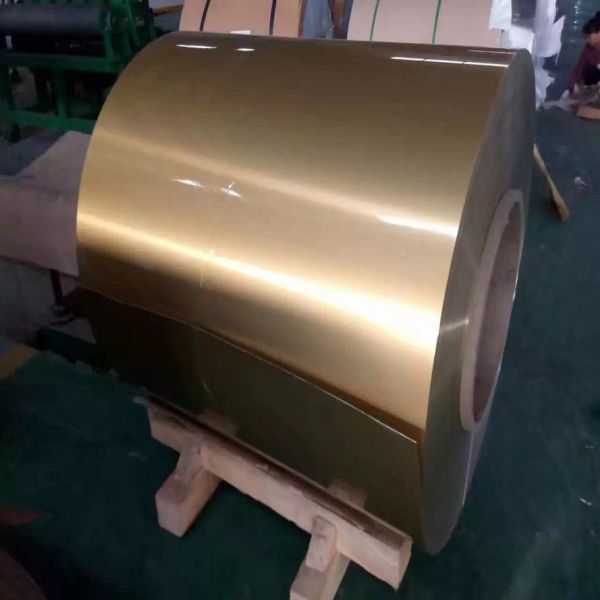

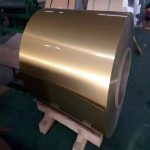

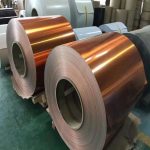

Color coated aluminum

Color coated aluminum:2024 aluminum is a typical hard aluminum alloy in the Al-Cu-Mg series. It is used most in 2 series alloys. And It’s not difficult to find that the strength of 2024 aluminum alloy is very high. When the temperature is higher than 125℃, its strength is higher than that of 7075 alloy. In addition, the heat treatment strengthening effect of the 2024 aluminum plate is the most significant. Whether it is in the hot state, annealed or newly hardened, its formability and machinability are very good. However, the heat treatment process of 2024 aluminum alloy is strict. It is mainly used for making various high load parts and components (but not stamping forgings) such as aircraft skeleton parts, skins, spacer frames, wing ribs, wing beams, rivets, and other working parts below 150 degrees.

| Grade | 2024 |

| Trade Terms | FOB/CNF/CIF |

| Supply Ability | 2000-3000 Ton/month |

| Packing | standard exporting packing or at buyer’s requirement |

| Width | 100-2200mm |

| Thickness | 0.6-1.35mm |

| Coating paint | PVDF/PE |

| Delivery time | Within 15-30days after we receive deposit or L/C at sight |

| Type | coil |

| Content | Performance of PE Coating | Performance of PVDF Coating |

| Color Difference | ∆E ≤ 2.0 | ∆E ≤ 1.5 |

| Gloss Difference | ≤5 | ≤5 |

| T-bend | ≤3T | ≤3T |

| Adhesion Grade | 0 | 0 |

| Impact | ≥20kg.cm | ≥50kg.cm |

| Solvent Resistance | 200 times no break | 200 times no break |

| Acidity Resistance | 5% HCL 24hrs no change | 5% HCL 24hrs no change |

| Alkali Resistance | 5% NaOH 24hrs no change color | 5% NaOH 24hrs no change color |

| Salt Spray Resistance | 720hrs ≤Grade le | 720hrs ≤Grade le |

| Abrasion Resistance | ≥5L/μm | ≥5L/μm |

Polyester Painted Aluminum Coil(PE)

The polyester painted aluminum coil is made by coating polyester paint which can form varied decorative film on the aluminum surface.Produced by advanced roller coating process, PE aluminum sheet has excellent painting and high performance. All the parameters of our products are able to meet or much higher than related national standards.

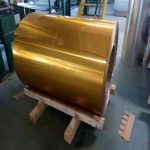

PVDF Coated Aluminum Coil

The PVDF coated aluminum coil uses PVDF paint of famous brands like PPG, VALSPAR and NIPPON, which goes through duplex or triplex coating and high temperature baking to form 25-35μm thick cured coating. As the PVDF.

coating provides corrosion resistance, high weatherability, strong adhesion, high self-cleaning capability and is maintenance-free, the aluminum coated coil can remain color fast and durable for 10-15 years.

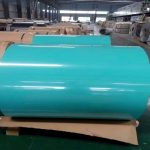

1.Exteror applications such as: wall cladding, facades, roofs and canopies, ACP, tunnels, column covers or renovations, etc.

2.Interior applications such as: wall cladding, ceilings, bathrooms, kitchens and balconies, etc.

3.Advertisement and market applications such as: display platforms, signboards, fascia and shop fronts, etc.

4.Transportation and industry, etc.