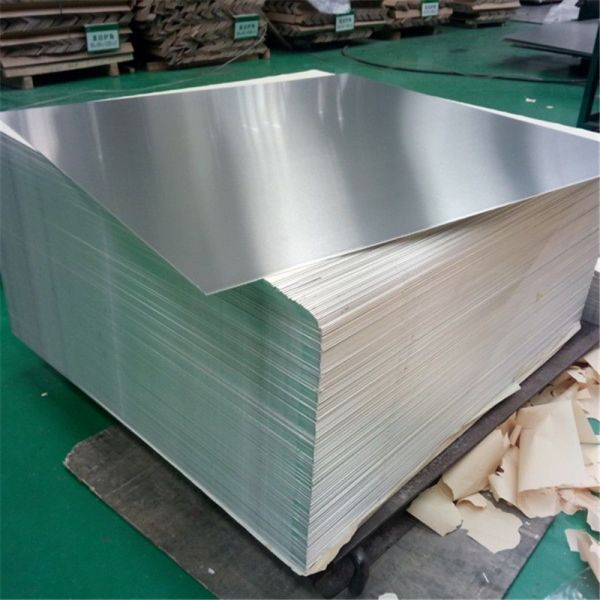

Hot Cold Drawn Aluminum Sheet 6101

Hot Cold Drawn Aluminum Sheet 6101:6101 aluminum is a 6000-series aluminum alloy: there is significant alloying with both magnesium and silicon, and the alloy is formulated for primary forming into wrought products. 6101 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-6101. 91E is the British Standard (BS) designation. E-AlMgSi is the common industry name. Additionally, the UNS number is A96101.

Hot Cold Drawn Aluminum Sheet 6101 is a popular alloy that can be found in many commercial and industrial applications. It can provide users with high electrical conductivity and good mechanical strength. Aluminum 6101 can be machined, welded and formed using standard methods, and it is easy to extrude.Hot Cold Drawn Aluminum Sheet 6101 is similar to 6063 aluminum plate, but the chemical change is small, which can enhance the conductivity. Although the conductivity is slightly lower than alloy 1350, Hot Cold Drawn Aluminum Sheet 6101 provides greater strength. Also, unlike other aluminum alloys, 6101Aluminum Sheet can be both hot and cold worked.

| Chemicai Composition(WT%) | |||||||||

| Grade | (Si) | (Cu) | (Mg) | (Zn) | (Mn) | (B) | (Cr) | Fe | (Al) |

| 6101 | 0.3-0.7 | ≤0.1 | 0.35-0.8 | ≤0.1 | ≤0.03 | ≤0.06 | ≤0.03 | ≤0.5 | Balance |

| Application | |||||||||

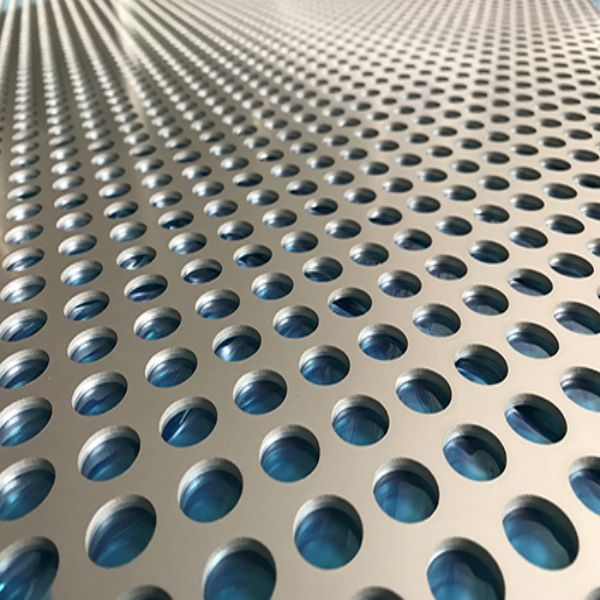

| Aluminum is one of the most commonly used conductive materials in the manufacture and construction of power distribution components and equipment. As a heat treatable forged product, 6101 aluminum plate is most suitable for applications with medium strength and maximum conductivity. Alloy 6101 is an important alloy in full line of bus conductor extruded products.

A variety of factors must be considered in bus design. Aluminum is desirable for bus conductors because it is only one-third the weight of copper, dissipates heat rapidly, is lightweight but very strong and highly corrosion resistant, and conducts an equal amount of electrical power with only half as much material weight as copper. With these properties, alloy 6101 also makes an excellent choice for electrical projects other than bus conductors. Electrical bus conductors and fittings Power transmission Power stations Electrical components |

|||||||||

1.What's your terms of payment?

30%T/T as the upfront deposit, 70% before delivery, We will show you the photos and package before you pay the balance.

2.What's the terms of delivery?

EXW, FOB, CFR, CIF

3. What's the terms of packing?

Generally,we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

4.What's your delivery time?

For stocks, we could transport the goods to loading port within 7 work days after we received the deposit.For productionperiod, it usually takes about 15 days to 30 days after we received the deposit.

5. Could you produce according to the samples?

Yes, we can customer-made by your samples or technique drawings, we can build the mold and fixtures.

6. Could youprovide the compliment samples?

Yes, we could provide the free samples on condition that it is available in stocks, however,the transportation fee is borne by buyer.

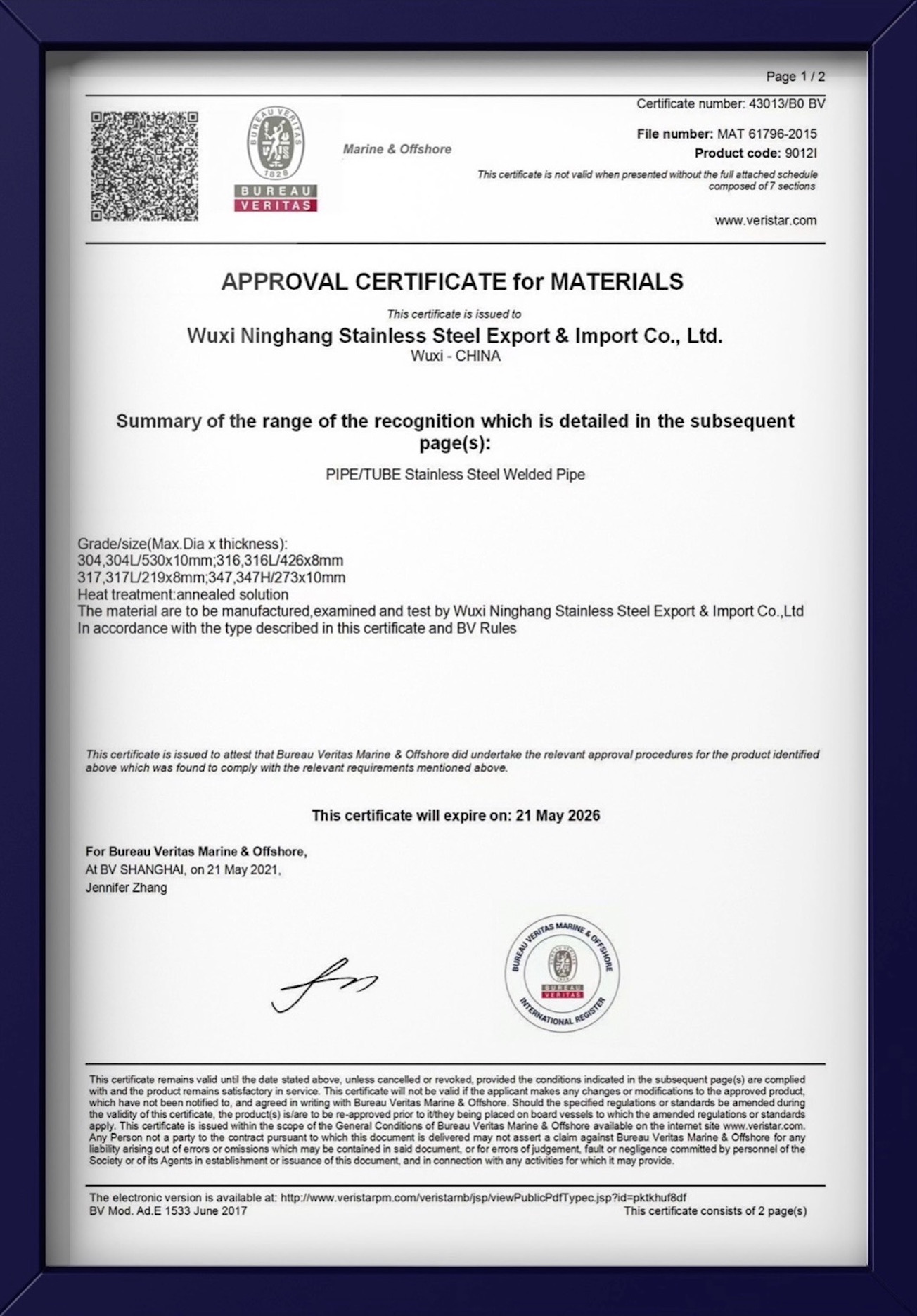

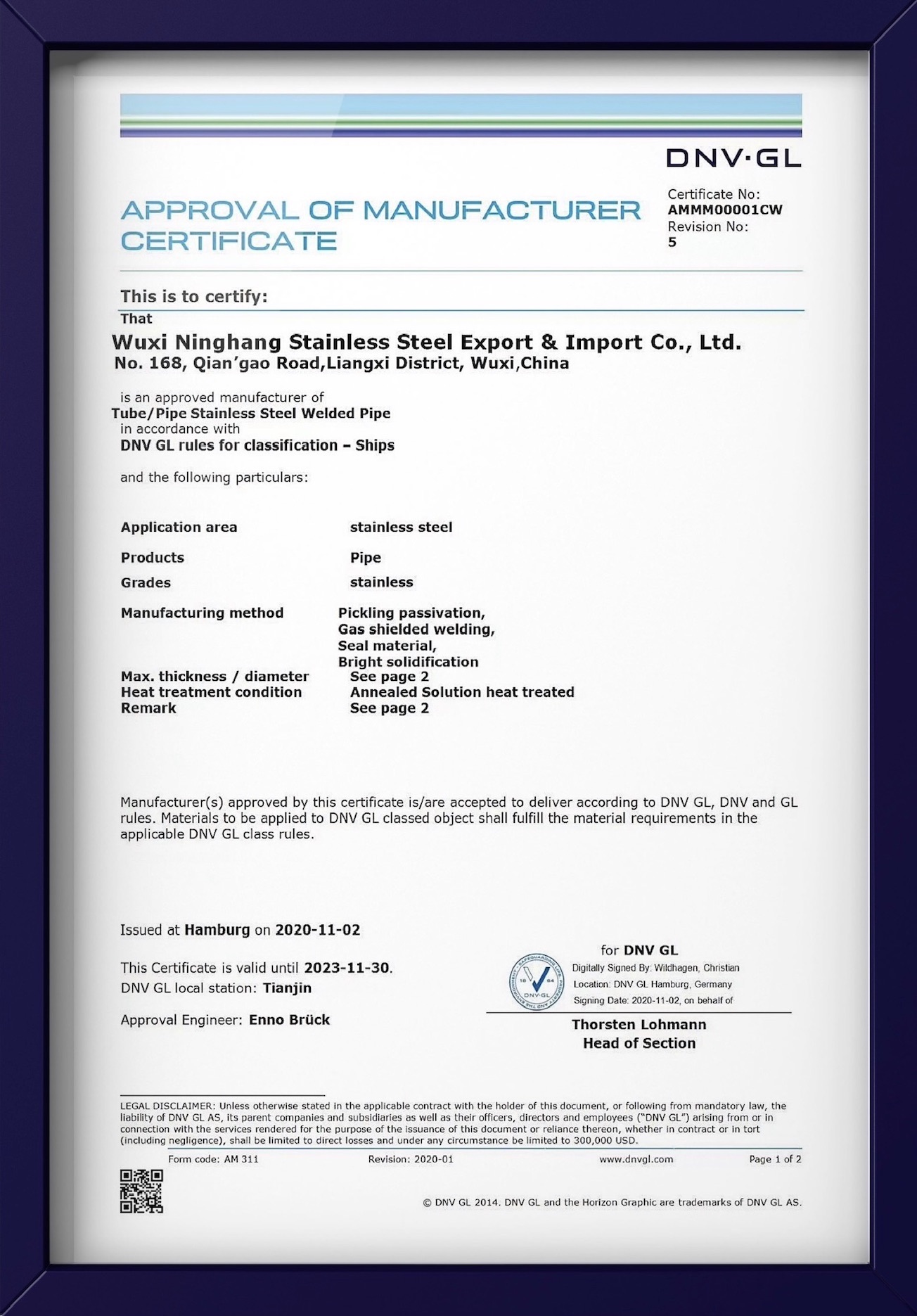

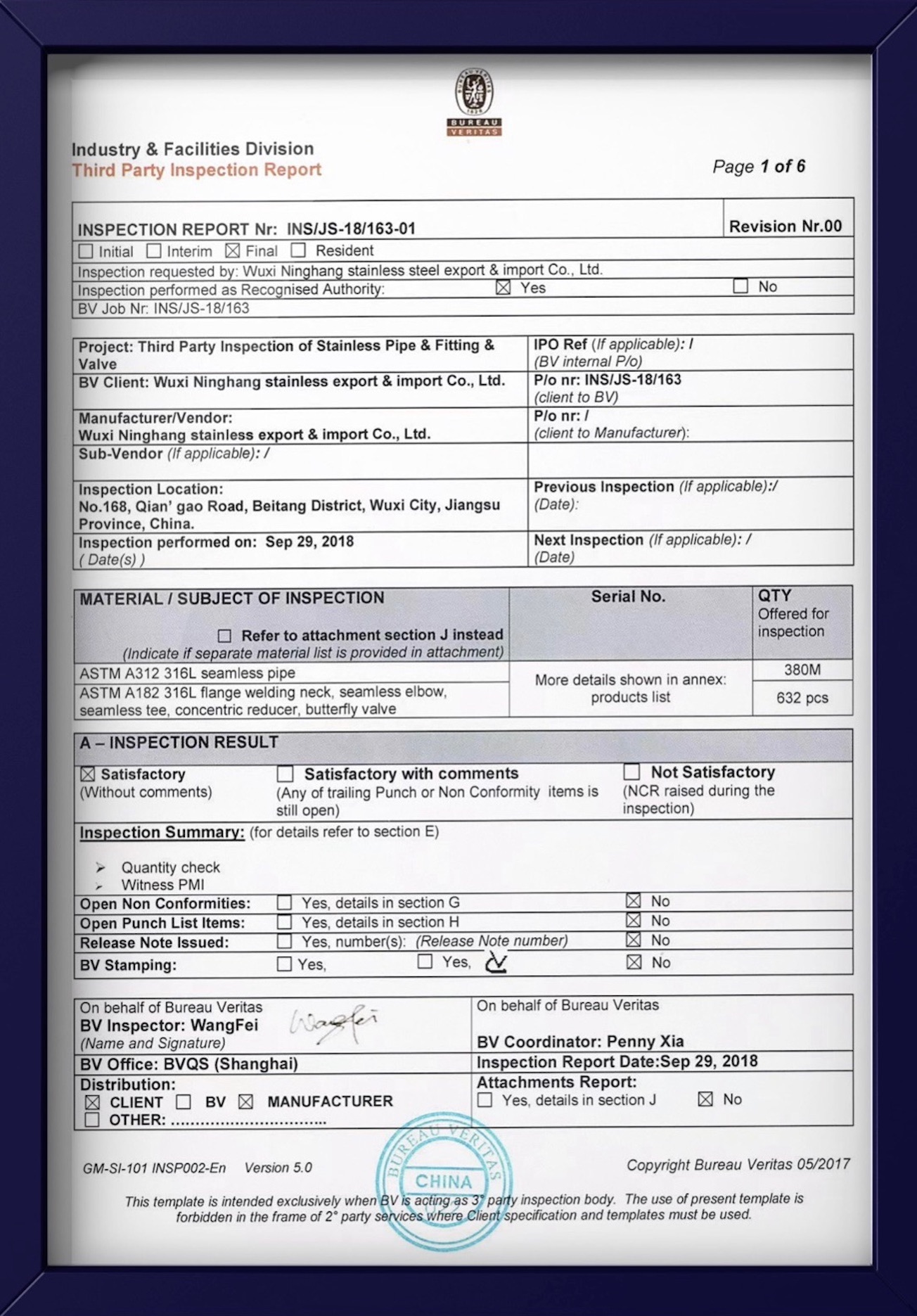

7. How could you guarantee your products quality?

Each piece of products is manufactured by certified workshops, inspected by us piece by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

7. What are the advantages of your company?

(1): Prime quality and reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.