Diversity and application of aluminum bars

02-29-24

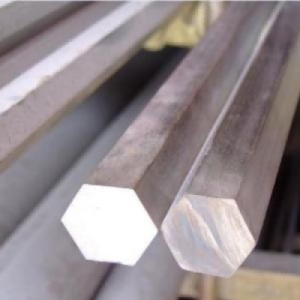

With the rapid development of modern industry and the continuous progress of science and technology, aluminum alloy bars, as an important metal material, show its unique value and wide application prospects in many fields. In this paper, the characteristics, manufacturing process and application fields of aluminum alloy bars are introduced in detail.

First, the characteristics of aluminum bars

Aluminum alloy bar is an alloy composed of aluminum and a small amount of other elements, with small density, high strength, good electrical and thermal conductivity, corrosion resistance and many other advantages. Compared with traditional steel materials, aluminum alloy bars have a lower density, thereby reducing the overall weight of the product, which is particularly important in aviation, automotive and other lightweight industries. In addition, aluminum alloy also has good electromagnetic shielding performance, widely used in electronics, communications and other fields.

Second, the manufacturing process of aluminum bars

The manufacturing process of aluminum alloy bars mainly includes melting, casting, rolling and heat treatment steps. In the smelting process, the ratio of aluminum to other alloying elements needs to be precisely controlled to ensure the properties of the alloy. In the process of casting, the aluminum alloy bar with excellent structure and mechanical properties can be obtained through reasonable mold design and casting technology. In the rolling process, parameters such as rolling temperature and rolling speed are controlled to make the aluminum alloy bar reach the required shape and size. The heat treatment process is used to further improve the mechanical properties and stability of aluminum alloy bars.

Third, the application field of aluminum bars

Aerospace field: Aluminum alloy bars are widely used in the aerospace field because of their low density, high strength and good corrosion resistance. Such as aircraft fuselage, engine support, satellite structure and other components are inseparable from the manufacture of aluminum alloy bars.

Automotive industry: With the acceleration of the trend of automotive lightweight, aluminum alloy bars are more and more widely used in the automotive industry. Such as engine cylinder block, wheel hub, frame and other components, the use of aluminum alloy bars can significantly reduce the weight of the car, improve fuel economy and environmental performance.

Construction field: The application of aluminum alloy bars in the construction field is mainly reflected in aluminum alloy doors and Windows, curtain walls, decorative panels and so on. Aluminum alloy material has excellent corrosion resistance and durability, which can meet the needs of long-term use of buildings.

Electronic and electrical fields: Aluminum alloy bars have good electrical conductivity and electromagnetic shielding properties, so they are also widely used in electronic and electrical fields. Such as the heat sink of electronic equipment, electromagnetic shielding cover, cable bridge and other components, can be made of aluminum alloy bars.

Packaging field: Aluminum alloy bars can also be used to make packaging materials, such as aluminum cans, aluminum foil, etc. These packaging materials have good sealing, light resistance and corrosion resistance, which can effectively protect the quality and safety of the contents.

In summary, aluminum alloy bars play a pivotal role in modern industry with their unique properties and wide application fields. With the continuous progress of science and technology and the continuous improvement of technology, the application prospect of aluminum alloy bars will be broader.