What are the properties of 5005 material?

03-29-24

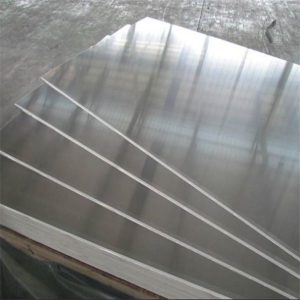

5005 material, commonly known as aluminum alloy 5005, is a non-heat-treatable alloy that belongs to the 5xxx series of aluminum alloys. This alloy is widely used in various applications due to its unique combination of mechanical properties and corrosion resistance. In this article, we will explore the properties of 5005 material in detail.

Composition

5005 aluminum alloy is primarily composed of aluminum, with approximately 0.8-1.3% magnesium added as the primary alloying element. It also contains small amounts of other elements such as chromium and iron to improve its corrosion resistance and mechanical properties.

High Strength-to-Weight Ratio

Aluminum alloys are generally lighter than steel or other metals, but 5005 material offers good strength and durability, making it suitable for use in applications where weight reduction is critical. This property is particularly beneficial in the aerospace, automotive, and construction industries, where lightweight materials are preferred.

Excellent Corrosion Resistance

The alloy's magnesium content helps to form a protective oxide layer on the surface, which prevents corrosion and extends the material's lifespan. This property makes 5005 material suitable for outdoor applications and exposure to harsh environments.

Good Formability and Workability

Aluminum alloy 5005 can be easily shaped and worked into complex geometries, making it suitable for a wide range of manufacturing processes. This formability allows for the creation of intricate components and structures that meet specific design requirements.

Good Conductivity

Aluminum alloy 5005 exhibits good electrical and thermal conductivity, making it useful in applications where these properties are crucial. For example, it can be used in electrical wiring or heat exchangers due to its ability to efficiently transmit electricity and heat.

Weldability and Brazeability

Aluminum alloy 5005 can be easily welded or brazed, facilitating the creation of strong and durable joints. This weldability allows for the construction of larger components or structures by joining multiple pieces together.

Non-toxic and Environmentally Friendly

Aluminum alloy 5005 is non-toxic and fully recyclable, making it an environmentally friendly material choice. Its recyclability reduces waste and the need for virgin materials, thus contributing to sustainable development and environmental preservation.

Applications

Due to its combination of properties, 5005 material is widely used in various applications. It is commonly found in automotive components, such as body panels and trim, as well as in building and construction materials like siding and roofing. Additionally, it is used in marine applications, electrical enclosures, and other industries that require corrosion-resistant materials.

In conclusion, the properties of 5005 material make it a highly versatile and desirable alloy for various applications. Its strength-to-weight ratio, corrosion resistance, formability, conductivity, weldability, and environmental friendliness combine to create a material that is well-suited for use in transportation, construction, electrical, and other industries. Understanding these properties can help engineers and manufacturers make informed decisions when selecting materials for their projects.