What is 1050 grade aluminium sheet?

05-08-24

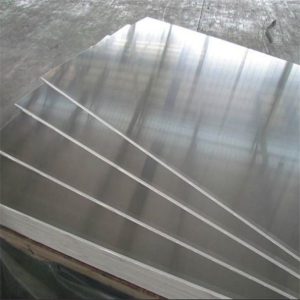

In the modern industrial field, aluminum alloy, as an important metal material, is widely used in various fields such as aviation, automobiles, construction and packaging. Among them, the 1050 grade aluminum alloy sheet has attracted much attention for its excellent performance and wide range of uses. In this paper, the properties, applications and production processes of 1050 grade aluminum alloy sheet will be discussed in depth.

The characteristics of 1050 aluminum alloy sheet

3003 aluminum alloy has a place in the construction industry with its good corrosion resistance and formability. Whether it is building wall panels, roof materials, or interior decorative panels, you can see the figure of 3003 aluminum alloy. These products are not only decorative, but also weather-resistant, able to maintain their original performance in a variety of harsh climatic conditions.

The application of 1050 aluminum alloy sheet

1050 aluminum alloy sheet is widely used in many fields due to its excellent performance:

Electrical circuits: Due to its high conductivity, 1050 aluminum alloy is often used to manufacture conductive parts of electronic components, such as wires, wires and circuit boards.

Cold rolled materials: 1050 aluminum alloy can be processed into thin sheets, foils and metal strips by cold rolling, often used in packaging materials, decorative materials and refrigeration equipment and other fields.

Fuel tanks and containers: 1050 aluminum alloy is suitable for the manufacture of fuel tanks, storage vessels and pressure vessels, etc., because of its good corrosion resistance.

Pipes and pipe fittings: 1050 aluminum alloy can be used in the manufacture of pipes and pipe fittings, such as HVAC systems, gas pipes and cooling water pipes.

Electrolytic capacitors: 1050 aluminum alloy is suitable for the manufacture of electrolytic capacitors because of its excellent conductivity and corrosion resistance.

The production process of 1050 aluminum alloy sheet

The production process of 1050 aluminum alloy sheet mainly includes raw material preparation, melting, rolling, annealing and surface treatment steps.

First, it is necessary to prepare high-quality pure aluminum as a raw material. Before production, the raw material needs to be melted to eliminate internal impurities and improve the purity of the material.

Next, the molten aluminum is rolled and pressed into sheets by rolling and stretching several times. The temperature and rolling force need to be controlled during the rolling process to obtain the ideal sheet thickness and flatness. The rolled aluminum sheet also needs to be annealed to eliminate residual stress and improve the toughness and ductility of the material.

Finally, the aluminum plate is treated to eliminate surface defects and burrs in the rolling process. Surface treatment methods include mechanical polishing, chemical polishing and anodizing. After these processing steps, the 1050 grade aluminum alloy sheet can meet a variety of application needs.

Conclusion

As an important metal material, 1050 aluminum alloy sheet has a wide application prospect in modern industry. Its high purity, good corrosion resistance and plasticity make the material widely used in electrical circuits, cold rolled materials, fuel tanks and containers, pipes and pipe fittings, and electrolytic capacitors. Through in-depth understanding of the nature, application and production process of 1050 grade aluminum alloy sheet, we can better play its advantages in industrial production and promote the development of related industries.