What is 3003 aluminum used for?

05-08-24

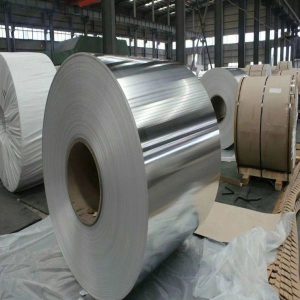

3003 aluminum alloy, as an AL-Mn alloy, is the most widely used rust-proof aluminum. Although the strength of this alloy is slightly higher than that of industrial pure aluminum, it is widely used in many fields due to its unique physical and chemical properties.

In the construction industry

3003 aluminum alloy has a place in the construction industry with its good corrosion resistance and formability. Whether it is building wall panels, roof materials, or interior decorative panels, you can see the figure of 3003 aluminum alloy. These products are not only decorative, but also weather-resistant, able to maintain their original performance in a variety of harsh climatic conditions.

In the aerospace field

3003 aluminum alloy also plays an important role. It is widely used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, siding and landing gear struts. The application of this material in the aerospace field mainly benefits from its light weight, high strength, corrosion resistance and other characteristics.

In the packaging industry

3003 aluminum alloy has also been widely used. Aluminum can can materials are mainly used as metal packaging materials in the form of sheet and foil, which are made into cans, caps, bottles, drums and packaging foils. This aluminum alloy not only has good plasticity, but also corrosion resistance, can effectively protect the packaging items, so that it is not damaged during transportation and storage. Therefore, it is widely used in beverage, food, cosmetics, medicines, cigarettes and other packaging.

Condenser manufacturing industry

The condenser is a device used to cool gas or steam into a liquid, and the 3003 aluminum tube has become an indispensable material in the condenser because of its good corrosion resistance and thermal conductivity. In air conditioning, refrigerators, automotive air conditioning and other fields, 3003 aluminum tubes have been widely used. In addition, this aluminum alloy is also widely used in compressed air pipelines, petrochemical equipment, food packaging, cosmetic packaging and other fields.

Conclusion

The application of 3003 aluminum alloy is extensive and diverse. From construction and transportation to packaging, printing, electronic appliances, aerospace, petrochemical and other fields, this alloy plays an important role. Its excellent physical and chemical properties, such as good corrosion resistance, sufficient strength, excellent process performance and welding performance, etc., make it widely used in many fields. In the future, with the continuous progress of science and technology and the continuous development of industry, the application field of 3003 aluminum alloy will be further expanded, and its role in human social life will be more important.