What is coil coated aluminum?

06-18-24

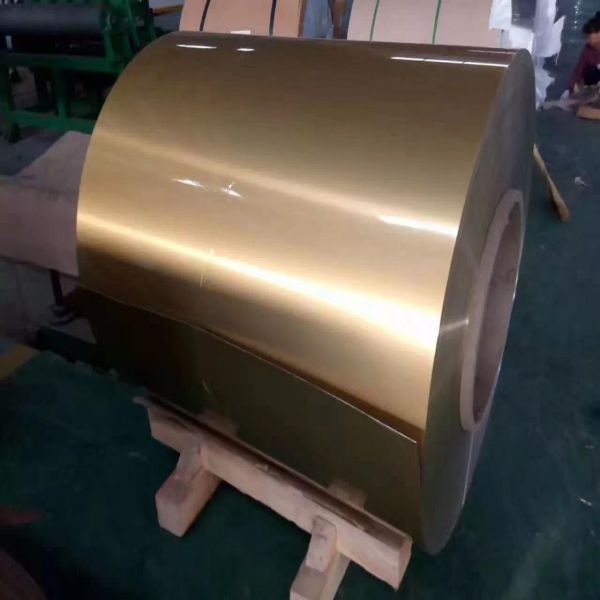

Roll-coated aluminum, also known as pre-coated aluminum, is a specially treated aluminum alloy material. This treatment process is mainly to coat the surface of the aluminum coil with one or more layers of organic coating, thus giving the aluminum more functions and characteristics. This material combines the light weight, corrosion resistance and plasticity of aluminum with the decorative and weather resistance of organic coatings, and is widely used in construction, home appliances, transportation and many other fields.

1) The basic definition of rolled aluminum

Roll-coated aluminum, as the name suggests, is an aluminum that has been treated by a continuous roll-coated process. In this process, the aluminum coil passes through a continuous coating line and its surface is evenly coated with one or more layers of paint. This treatment not only enhances the corrosion resistance and weather resistance of the aluminum, but also gives it a rich choice of colors and textures.

2) The production process of coil coated aluminum

The production process of coil coated aluminum can be roughly divided into the following steps: First, select high-quality aluminum alloy coil as the base material; Next, the substrate is cleaned and pretreated to remove oil and oxide from the surface to ensure that the coating can firmly adhere to the aluminum; Then, the surface of the pre-treated aluminum is coated with one or more layers of organic coating, which can be polyester, fluorocarbon, acrylic and other materials, according to the use of environment and performance requirements to choose different coating materials and thickens; Finally, through drying, curing and other processes, the coating and aluminum are closely combined to form a coil coated aluminum with excellent properties.

3) Application Areas

In the construction industry, roll-coated aluminum has been widely favored for its beautiful, durable and easy to maintain characteristics. It is widely used in building curtain walls, roofs, exterior wall decorative panels and other aspects, giving the building a sense of modernity and fashion. In addition, in the field of transportation, roll-coated aluminum also plays an important role. Whether it is a car body, train car or aircraft shell, roll-coated aluminum can provide excellent protective performance and aesthetic effect.

In addition to the above industries, roll-coated aluminum is also widely used in household appliances, electronic products, billboards and other fields. For example, in the field of home appliances, roll-coated aluminum is used to make the shell of refrigerators, washing machines and other home appliances, which is not only beautiful, but also easy to clean and maintain. In the field of electronics, its light weight and high electrical conductivity make coil coated aluminum an ideal material for components such as circuit boards and heat sinks. In the production of billboards, the rich color and texture choices of rolled aluminum make the billboards more eye-catching and eye-catching.

4) Concliusion

Roll-coated aluminum is gradually becoming an indispensable part of modern industry with its unique properties, a wide range of application fields and innovative processing technology. With the continuous progress of science and technology and the improvement of people's requirements for material performance, we have reason to believe that roll-coated aluminum will play a more important role in the future, providing strong support for the development of all walks of life.