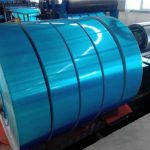

Color coated aluminum rolls

PVDF Color coated aluminum rolls:Zn is the mainly alloy elements of 7050 aluminum strip. Adding magnesium into the 7050 alloy which contains 3% -75% of Zn forms a significant strengthening effect of MgZn2 and makes the effect of heat treatment far better than Al-Zn binary alloy. 7050 belongs to the high-strength heat-treatable alloy, aviation superhard aluminum alloy, good wear resistance,Color coated aluminum rolls high strength, , Color coated aluminum rolls with extremely high strength and anti-spalling corrosion and stress corrosion fracture resistance. Good plasticity after solid solution treatment, good strengthening effect of heat treatment, good strength under 150℃, and especially good low-temperature strength, poor welding performance, stress corrosion cracking tendency.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | — | 0.05 | 0.03 | 99.5 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | — | 0.04 | 0.03 | 99.7 |

| 1100 | 0.95 Si + Fe | 0.05-0.20 | 0.05 | — | — | 0.1 | — | 99 | |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.30-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | Rem. |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | — | — | 0.1 | — | Rem. |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | — | 0.25 | — | Rem. |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.20-0.6 | 0.1 | 0.25 | 0.1 | Rem. |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50-1.1 | 0.1 | 0.25 | — | Rem. |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1

|

— | Rem. |

| 5252 | 0.08 | 0.1 | 0.1 | 0.1 | 2.2-2.8 | — | 0.05 | — | Rem. |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | Rem. |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | Rem. |

| Alloy | Temper | Tensile Strength | Yield Strength | Elongation (%) | Tensile Strength | Yield Strength | |

| (ksi) | (ksi) | 0.01-0.05 in | 0.051-0.125 in | (MPa) | (MPa) | ||

| 1100 | H12 | 16 | 15 | 4 | 12 | 110.3 | 103.4 |

| H14 | 18 | 17 | 3 | 10 | 124.1 | 117.2 | |

| 3003 | H12 | 19 | 18 | 9 | 11 | 131 | 124.1 |

| H14 | 22 | 21 | 3 | 7 | 151.7 | 144.8 | |

| 3004 | H32 | 31 | 25 | 6 | 15 | 213.7 | 172.4 |

| H34 | 35 | 29 | 5 | 10 | 241.3 | 199.9 | |

| 3005 | H12 | 26 | 24 | 5 | 13 | 179.3 | 165.5 |

| H14 | 29 | 28 | 4 | 9 | 199.9 | 193.1 | |

| 5005 | H12 | 20 | 19 | 5 | 9 | 137.9 | 131 |

| H14 | 23 | 22 | 4 | 7 | 158.6 | 151.7 | |

| 5052 | H32 | 33 | 28 | 7 | 10 | 227.5 | 193.1 |

| H34 | 38 | 31 | 6 | 8 | 262 | 213.7 | |

| 5056 | O | 42 | 22 | 23 | 24 | 289.6 | 151.7 |

| H38 | 60 | 50 | 6 | 13 | 413.7 | 344.7 | |

| 6061 | T4 | 35 | 21 | 22 | 24 | 241.3 | 144.8 |

| T6 | 45 | 40 | 12 | 17 | 310.3 | 275.8 | |

| 7075 | O | 33 | 15 | 16 | 18 | 227.5 | 103.4 |

| T6 | 83 | 73 | 11 | 12 | 572.3 | 503.3 | |

It is mainly used for manufacturing aircraft structures and other high-stress structures requiring high strength and corrosion resistance, such as aircraft upper and lower wing face panels, girder bars, etc.

Widely used in mold processing, mechanical equipment, fixture, aerospace industry, blow molding (bottle) mold, ultrasonic plastic welding mold, golf ball head, shoe mold, paper mold, foam molding mold, wax mold, mechanical equipment, used for making high-end aluminum alloy bicycle frame.