Thin walled aluminum tube 5005

Thin walled aluminum tube 5005 :5005 aluminum pipe belongs to 5-series Al-Mg alloy, but the content of the main alloy Mg is less than that of other 5-series alloy, so it has a slightly higher corrosion resistance than the 3-series alloy. Among them, the performance of 5005 aluminum alloy is similar to that of 3 series 3003 aluminum alloy, with moderate strength, good fusion, processing and formability, but its anodic oxidation effect is better than that of 3003 aluminum alloy, the oxide film is brighter, and can achieve the same color as that of 6063 alloy.

General Features: 5005 is a non-heat treatable alloy with magnesium content. It can be strengthened (hardened) by cold working. It scores well in weld-ability, form ability, and corrosion resistance (especially when anodized).

Forming: 5005 has excellent form ability, especially in softer tempers.

Welding: 5005 alloy is noted for excellent welding characteristics. When 5005 material will be welded and then anodized, we recommends a 5356 welding wire for best color uniformity. Weld discoloration can still occur, but it is less severe than other welding alloys.

Machining: 5005 machine ability is generally fairly poor. Soft 5005 tempers machine worse than harder tempers. 5005 H34 and 5005 H38 can be machined, but with much more difficulty than many other aluminum alloys.

| Product Name | aluminum pipe |

| Shape | Round,Square,Rectangular,Oval,half-round |

| Color available | Silver, Bronze, champagne, Matte, Natural for anodizing, RAL for powder coating |

| Out Diameter | 2mm-2500mm or as the customer’s request |

| Thickness | 0.5mm-150mm or as the customer’s request |

| OEM Service | Perforated, Cutting special size, Doing flatness, Surface treatment,etc |

| Delivery Time | Within 3 days for our stock size,7-15 days for our production |

| MOQ | 100kg |

| Usage | 1.LED light industry 2.Solar industry 3.Sanitary industry 4.Auto party industry 5.Heat sink industry and etc |

| Surface treatment | Mill finish, anodized, powder coated, electrophoresis, sand blasting, wood grain painting, matted, polishing bright etc. |

| Standard | GB/T6893-2000,GB/T4437-2000,ASTM B210,ASTM B241,ASTM B234,JIS H4080-2006,etc |

1.Welding technology of thin-walled copper-aluminum tubes suitable for industrialized production.

2.The surface material can effectively prevent corrosion and extend the service life to a great extent.

3.Strong plasticity, suitable for a variety of working environments.

1.How long will it take to execute my order?

Our normal lead time is 7-15 working days.,but we have many models in stock,We will let you know the estimated lead time after payment ASAP.

2. How do you control quality?

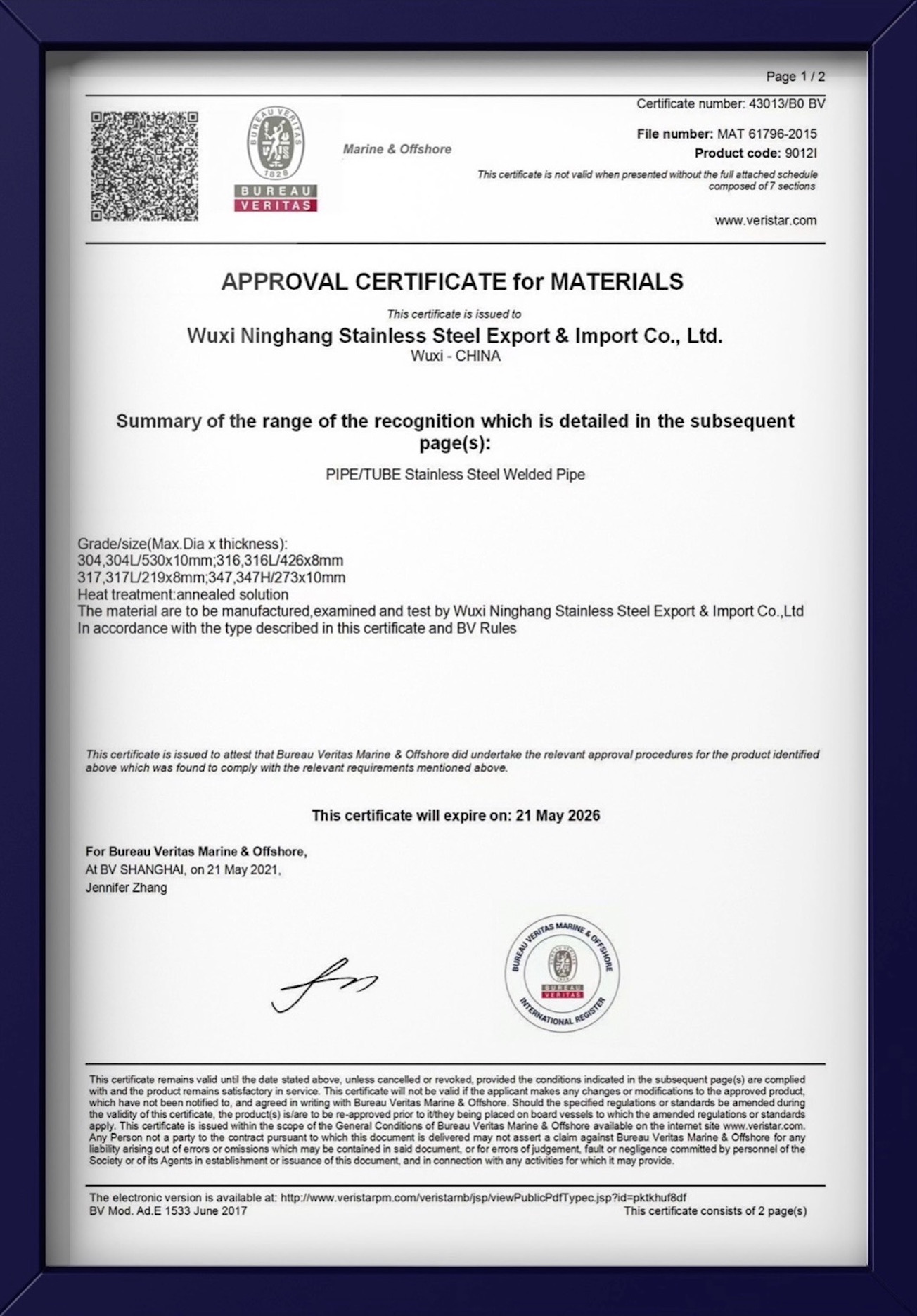

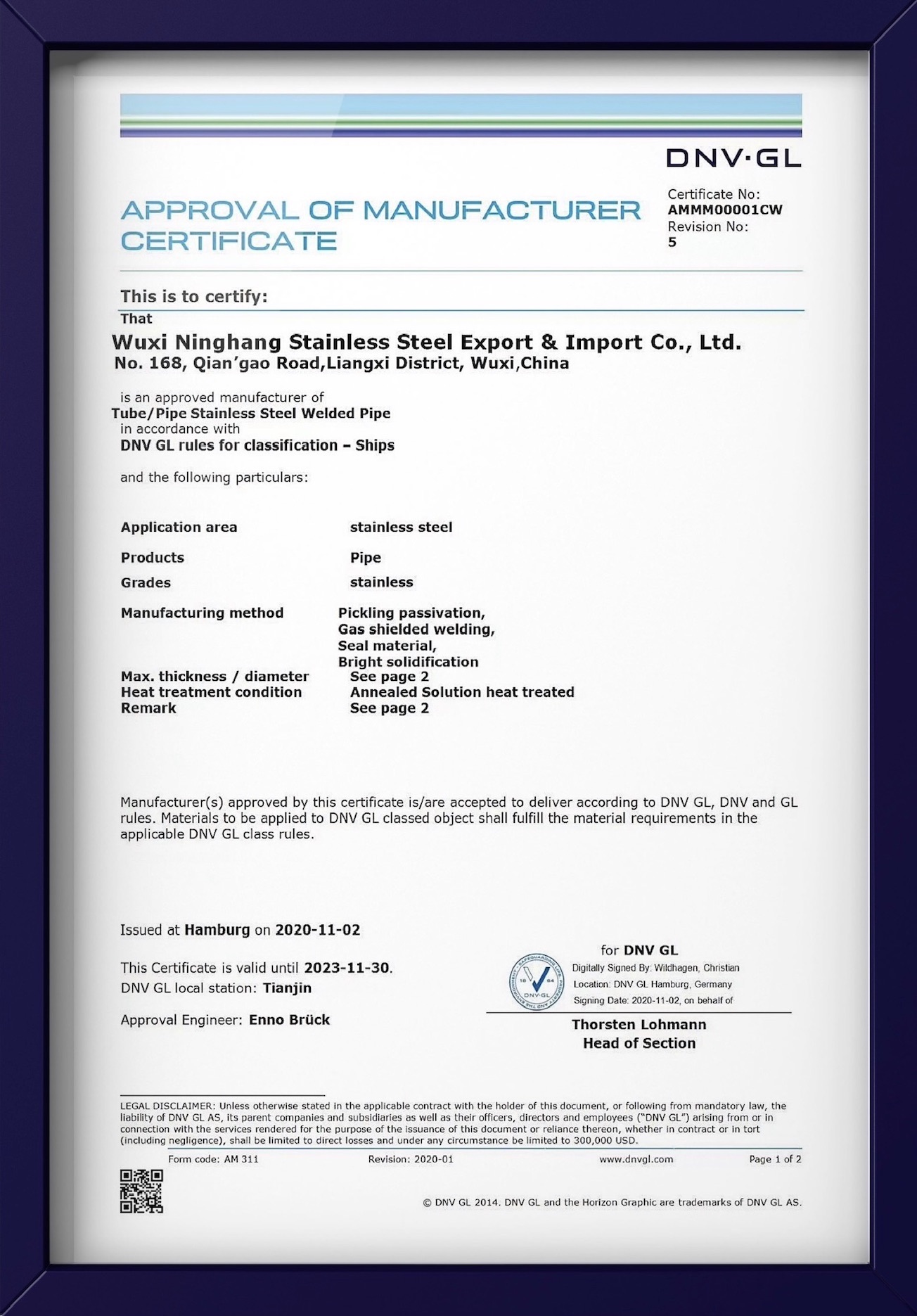

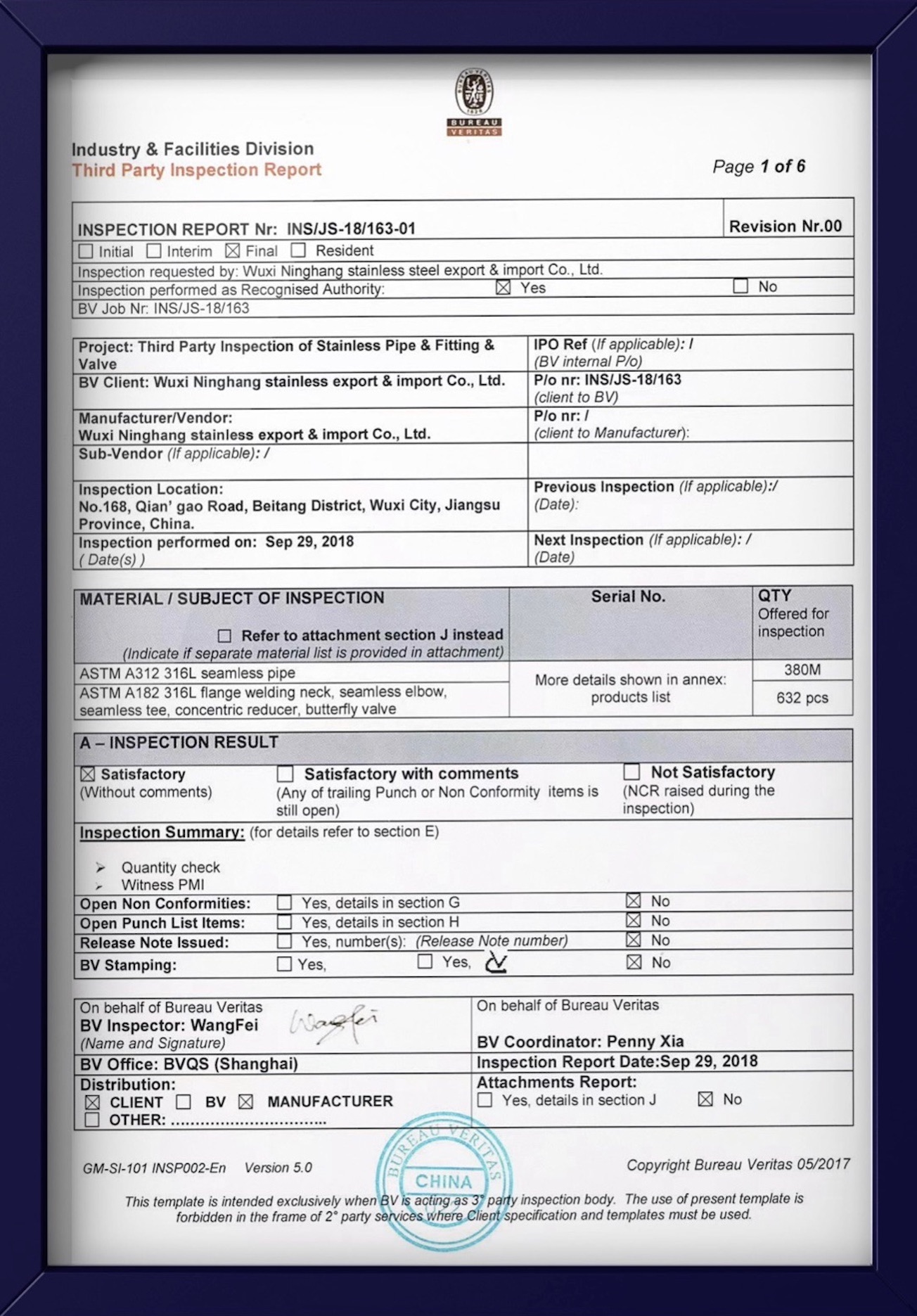

Mill Test Certification is supplied with shipment, Third Party Inspection is available. and we also get ISO,SGS,CE.

3.What are the advantages of your company?

We have many professionals, technical personnel, more competitive prices and best after-dales service than other companies.